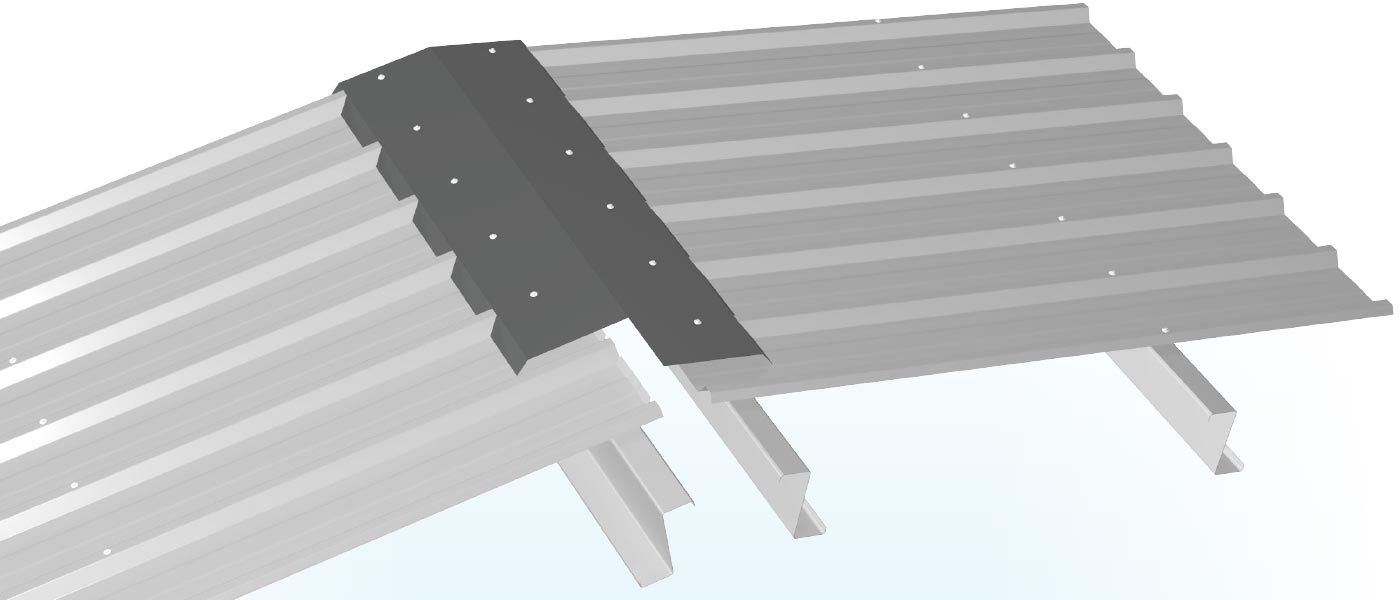

Flashings

StratcoSKU: Flashings

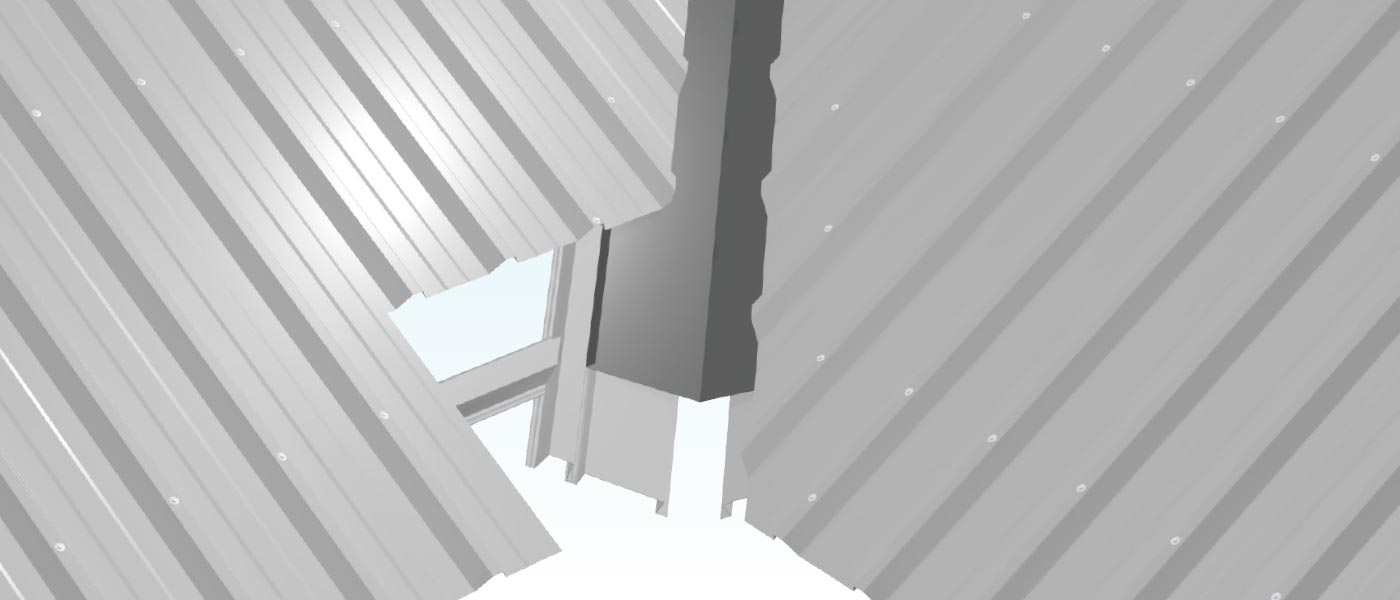

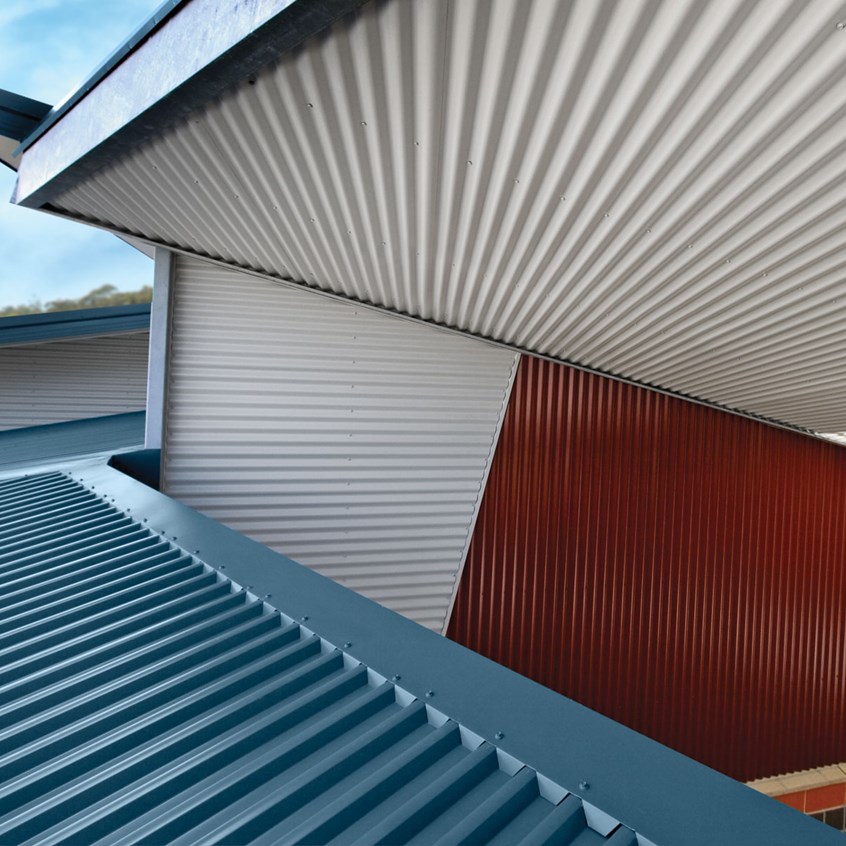

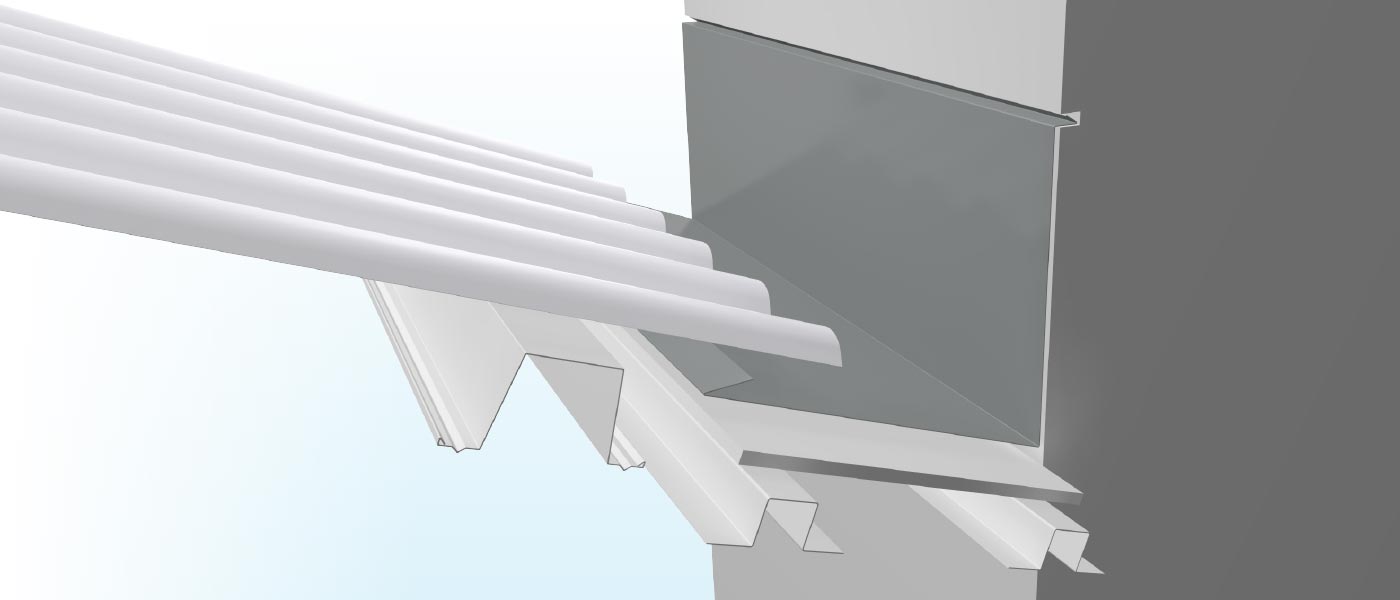

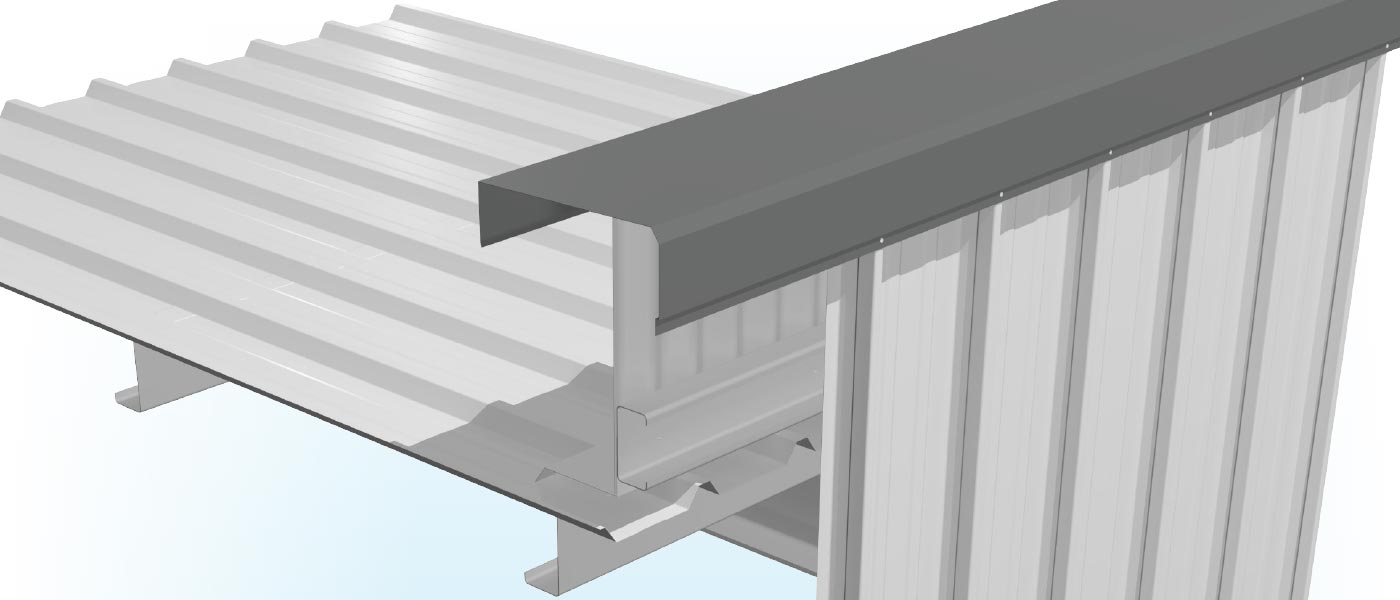

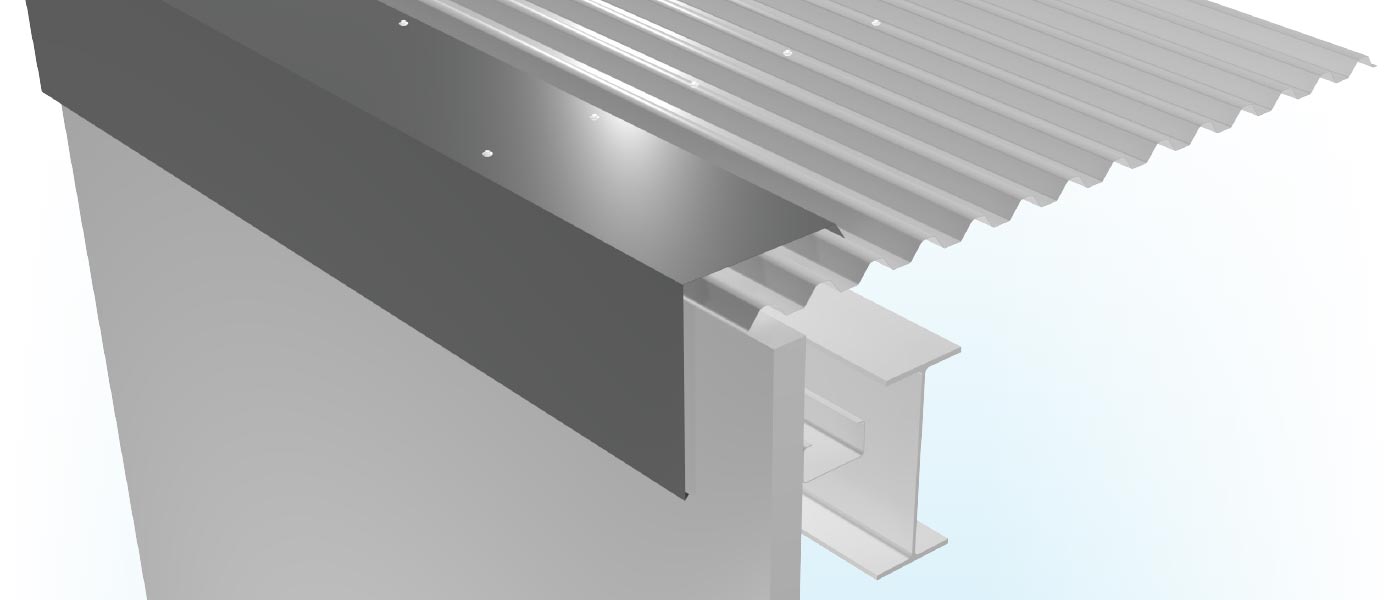

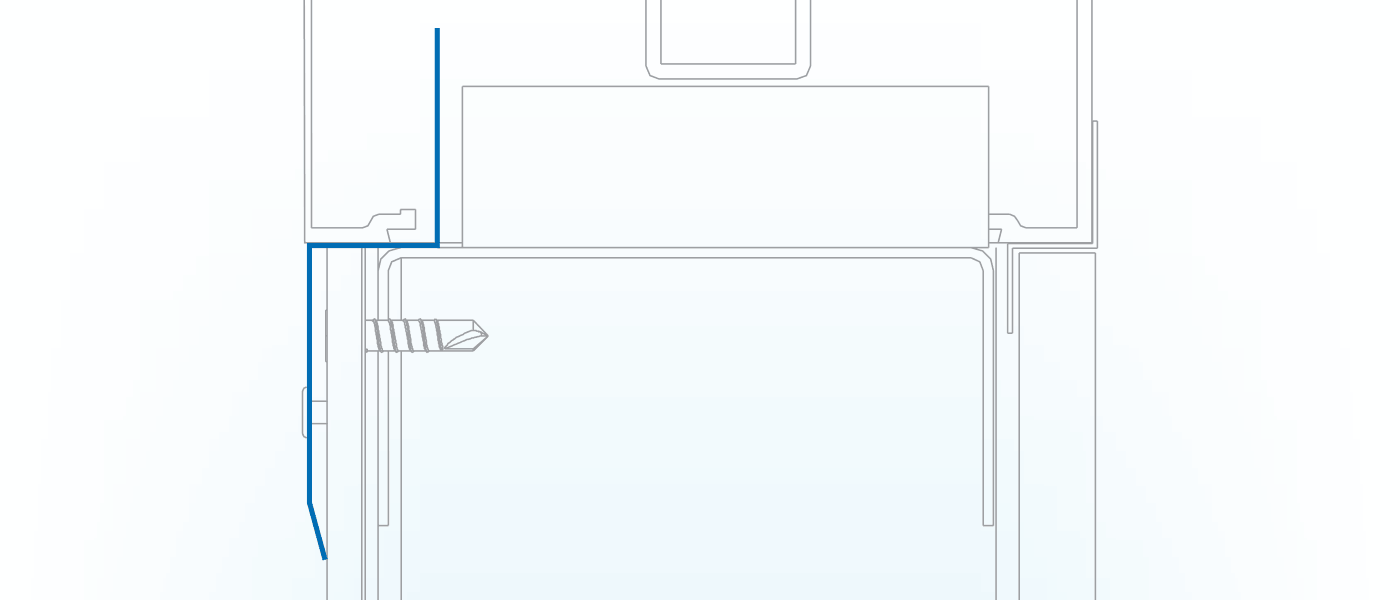

Stratco can fold a wide range of standard or custom flashings to suit your requirements. Flashings are available in pre-painted steel, zinc/al, aluminium, stainless steel, and copper. Choose from a wide range of available thicknesses from 0.4mm to 3.0mm depending on your state. Whether you want to install it yourself or require assistance, we are here to help. Contact us for pricing and further details today.Image gallery

Order your Stratco flashings in a flash!

NEW Flashing Design Tool

Order a flashing using the designer today, and have it by tomorrow ... No fuss!

Whether you are on-site, on a roof, or in your office, you can order your flashings direct with Stratco using your desktop, phone or tablet.

Brochures & Installation Guides

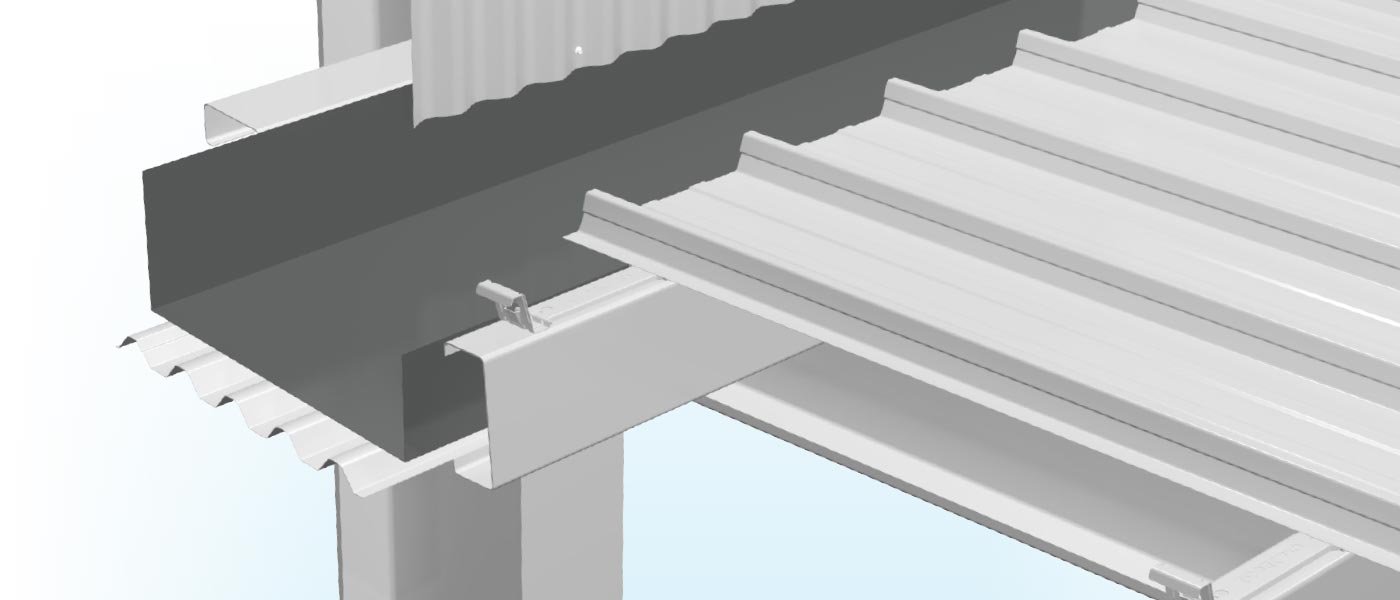

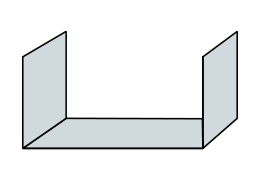

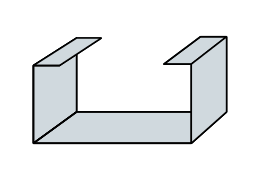

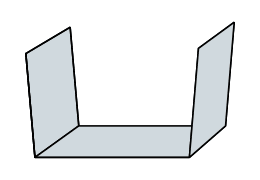

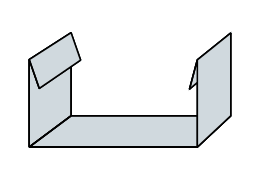

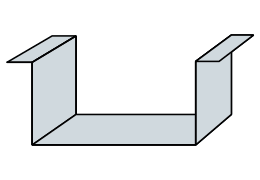

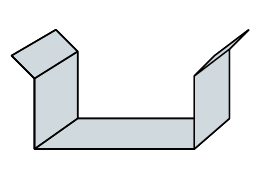

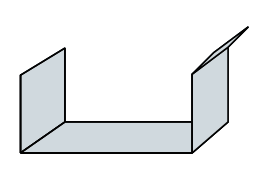

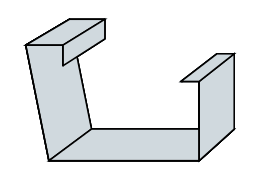

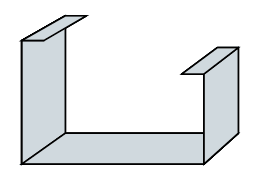

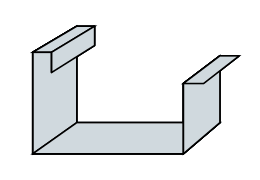

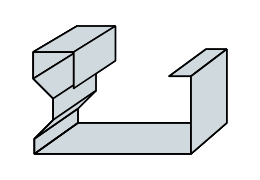

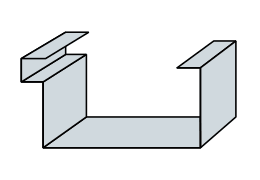

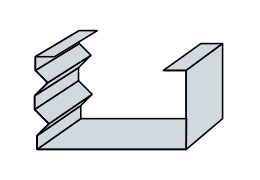

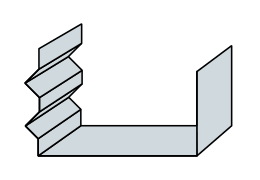

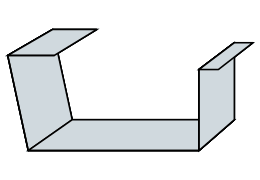

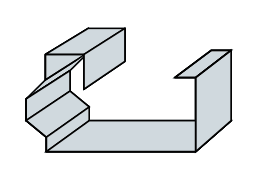

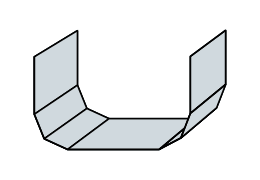

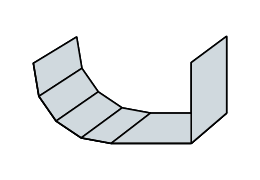

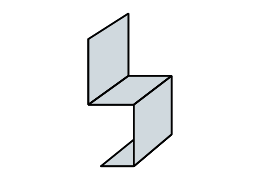

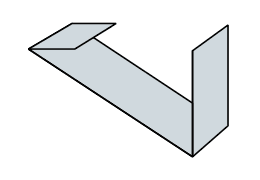

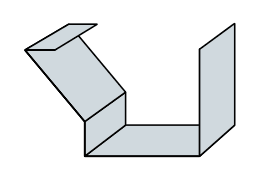

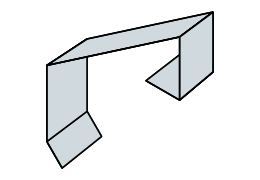

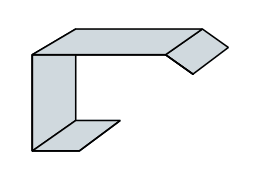

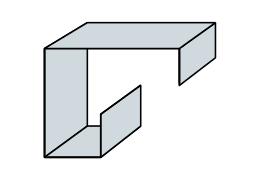

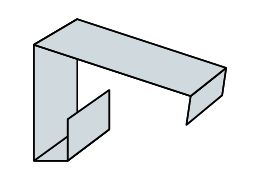

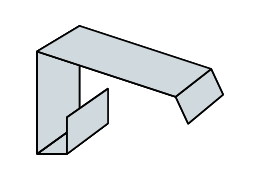

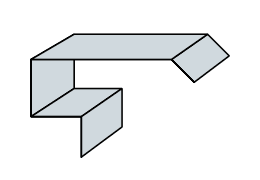

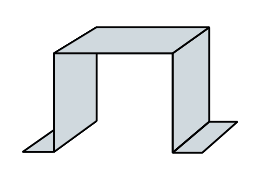

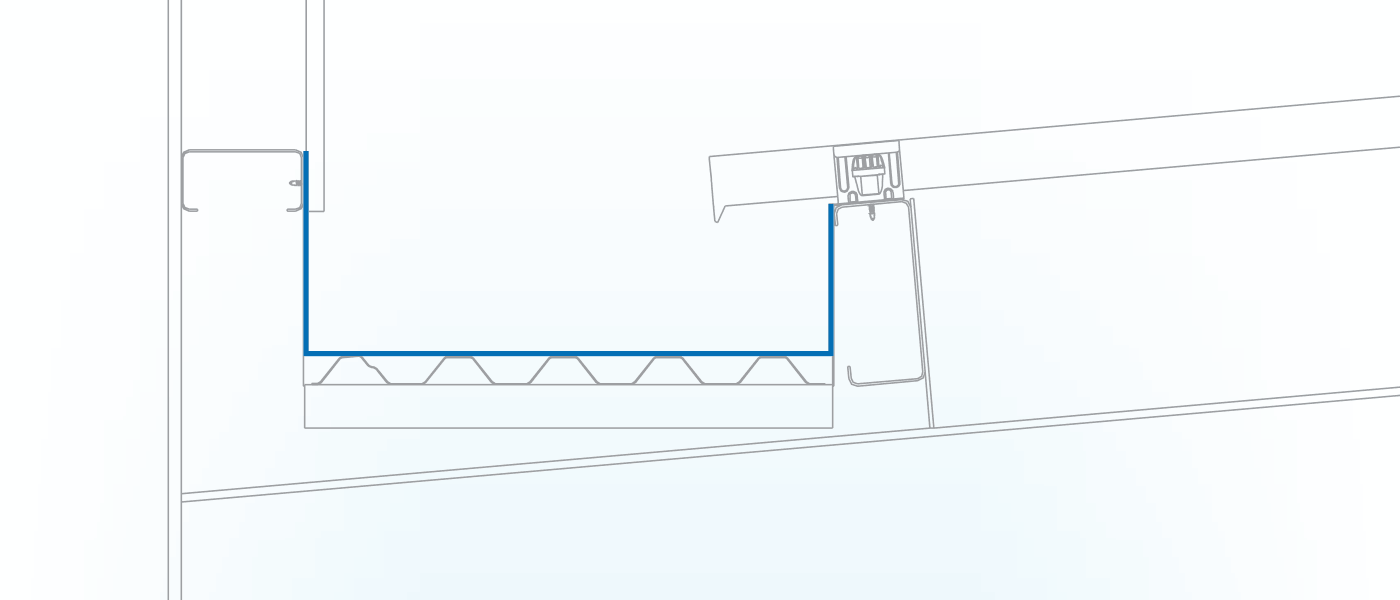

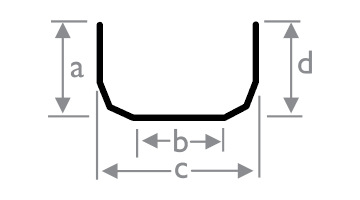

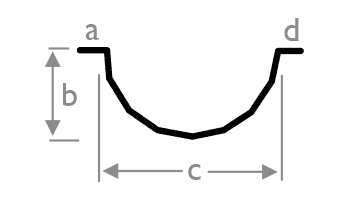

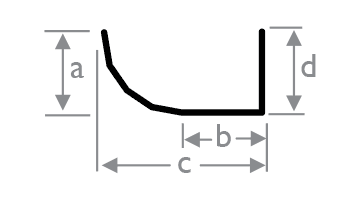

Box Gutters

A square or rectangular gutter that is used within the boundaries of the roof. It may be formed between a roof surface and a parapet wall or between two roof surfaces. Available with infold, outfold, splashback and squashfold edges. This gutter is usually supported on a box gutter board to improve strength and stiffness and to minimise damage caused by roof traffic.

1

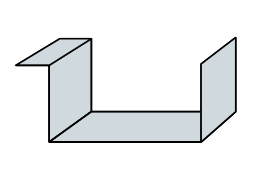

Standard Box Gutter

2

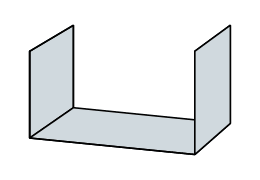

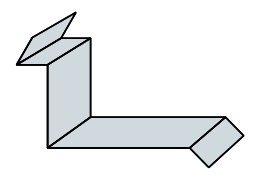

Box Gutter

With Single Outfold

3

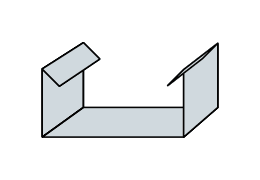

Angled Box Gutter

4

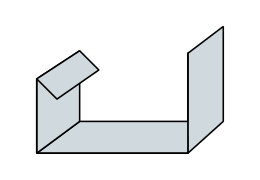

Box Gutter

With Double Splashbacks

5

Box Gutter

With Single Splashback

6

Box Gutter

With Double Infolds

7

Box Gutter

With Double Splay

8

Box Gutter

With Squashfolds

9

Box Gutter

With Double Outfolds

10

Box Gutter

With Double Upturns

11

Box Gutter

With Single Upturns

12

Box Gutter

With 'V' Stiffening Rib

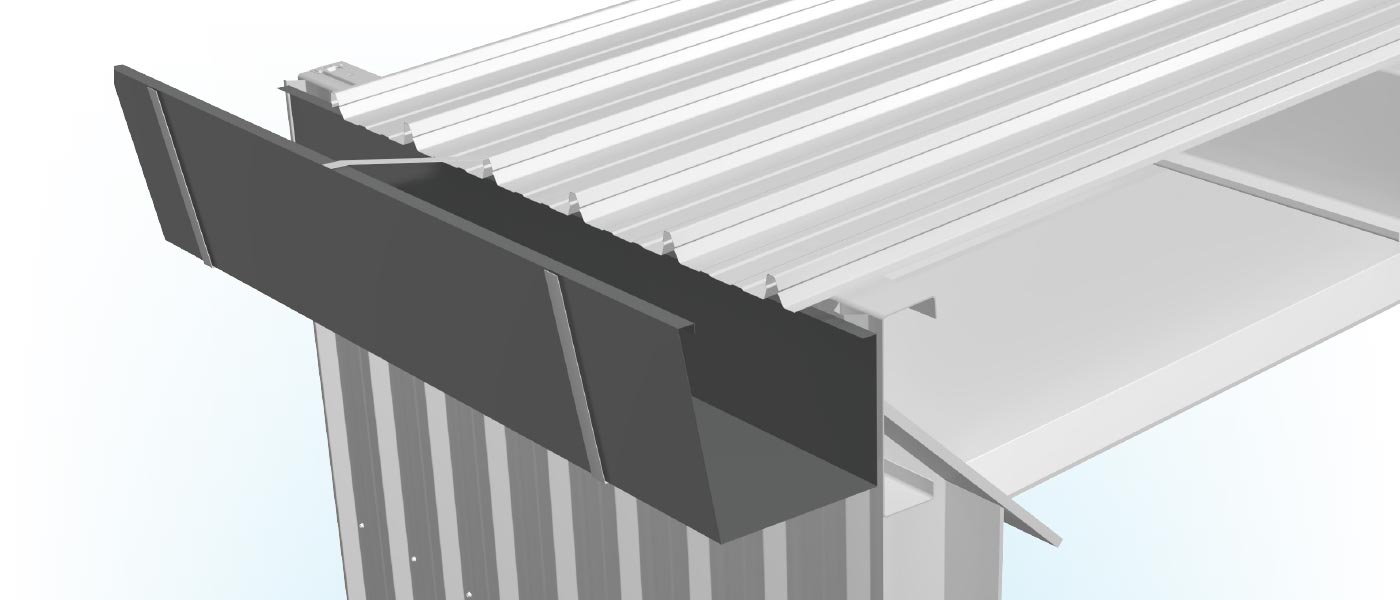

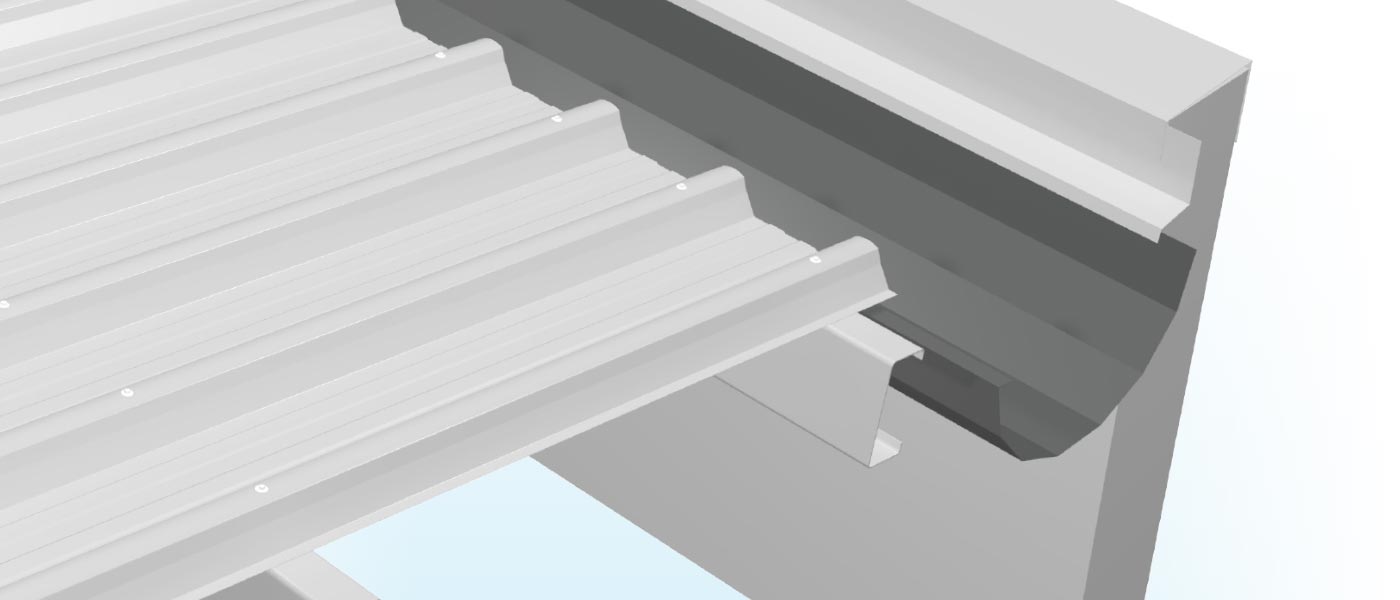

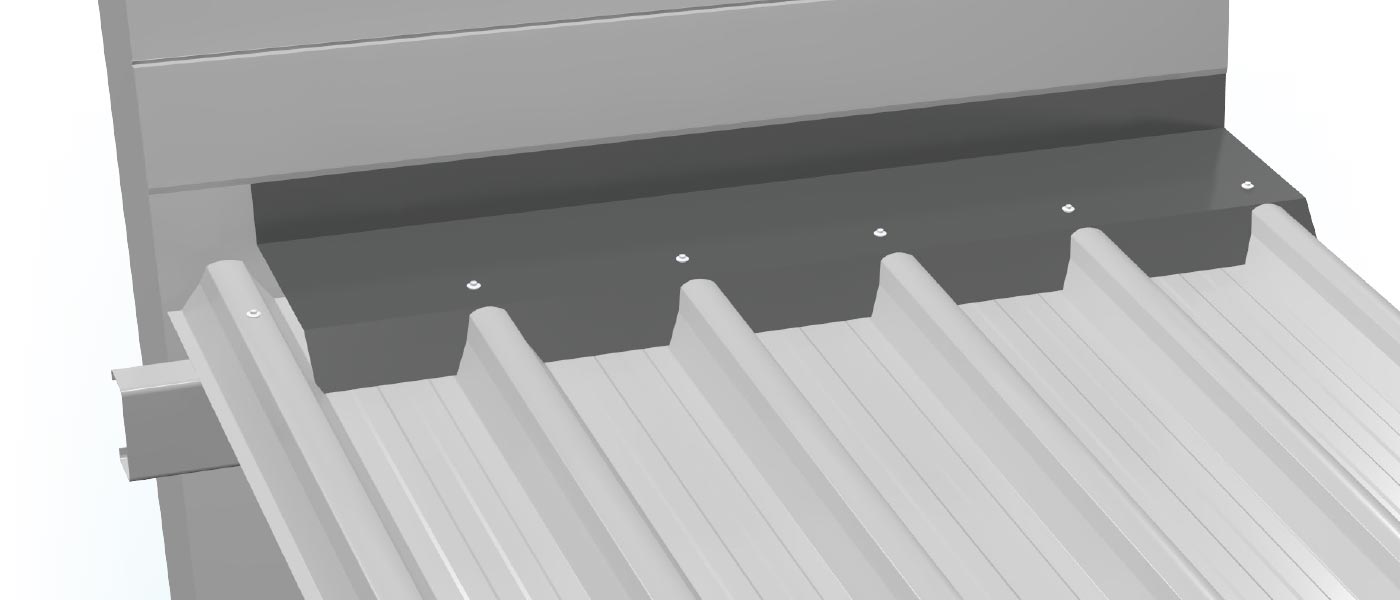

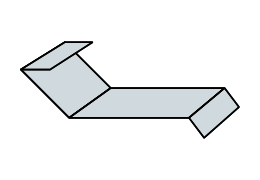

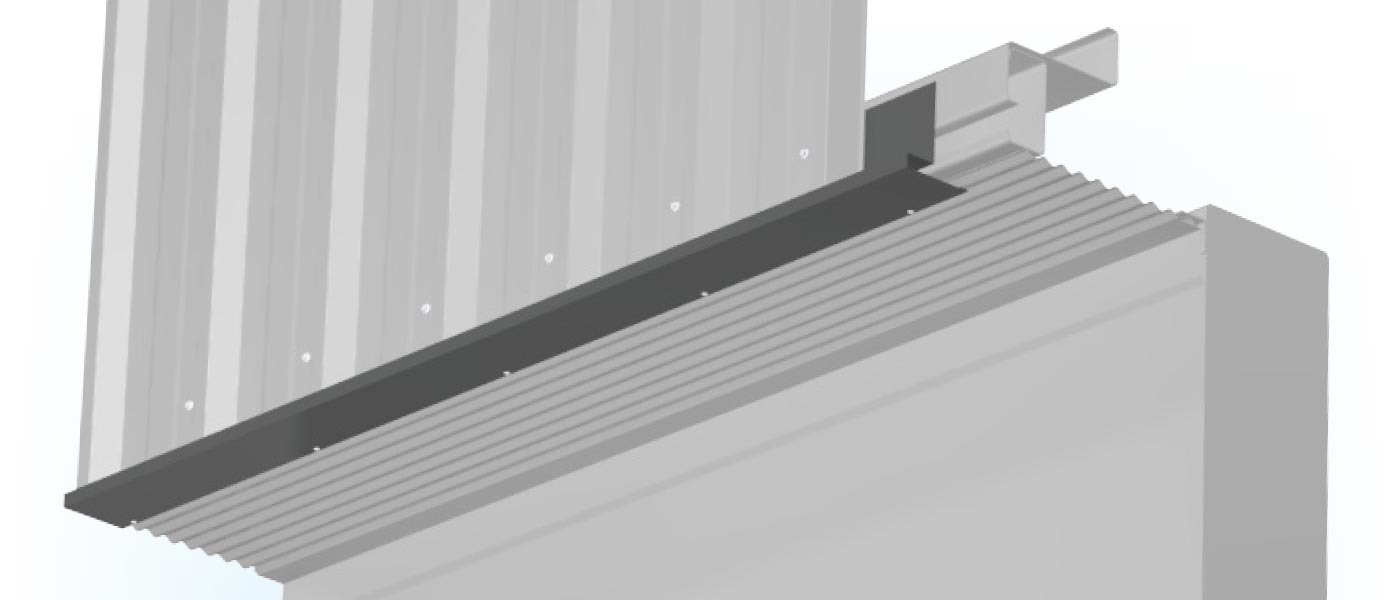

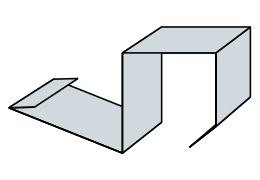

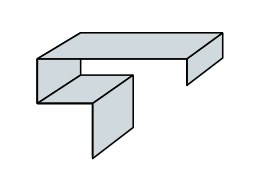

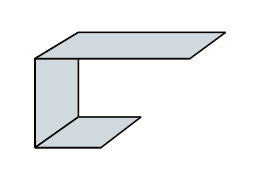

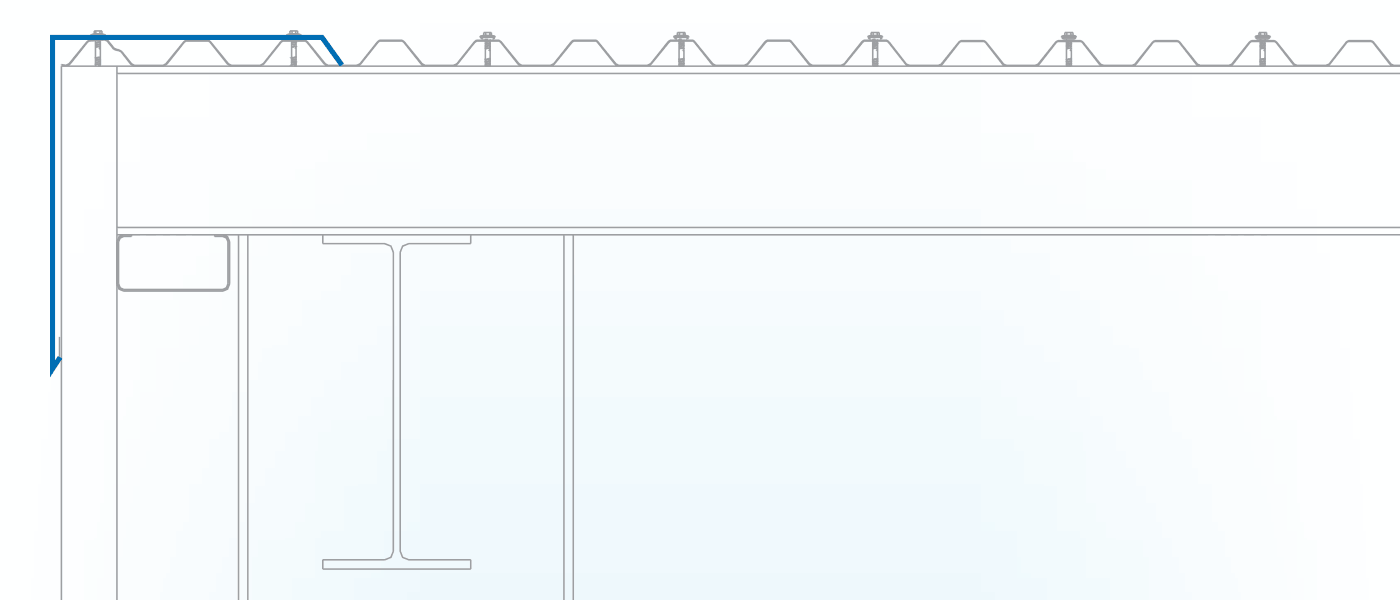

Industrial Eave Gutters

A purpose made external gutter which is located at the edge of an industrial roof. It is usually supported by heavy gauge brackets that have been designed specifically to suit the industrial eaves gutter shape. When made in larger sizes special attention should be given to minimising oil canning of flat surfaces by adding extra ribs into the design.

13

Industrial Eaves Gutter

With Return

14

Basic Industrial

Eaves Gutter

15

Industrial Eaves

With Outfold

16

Industrial Eaves

With Stiffening Rib

17

Industrial Eaves Gutter

With Bead

18

Fancy Industrial Eaves

Gutter With Bead

19

Two Rib Industrial

Eaves Gutter

20

Industrial Eaves Gutter

With Splay And Outfold

21

Industrial Eaves Gutter

With Protruding Rib

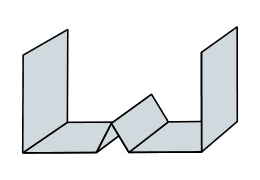

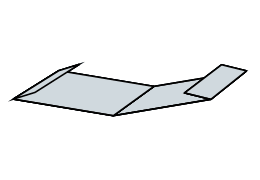

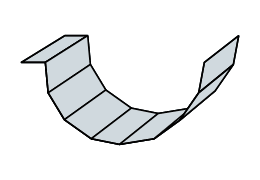

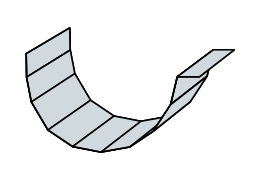

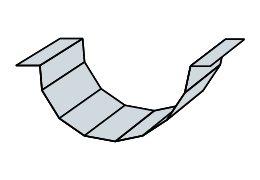

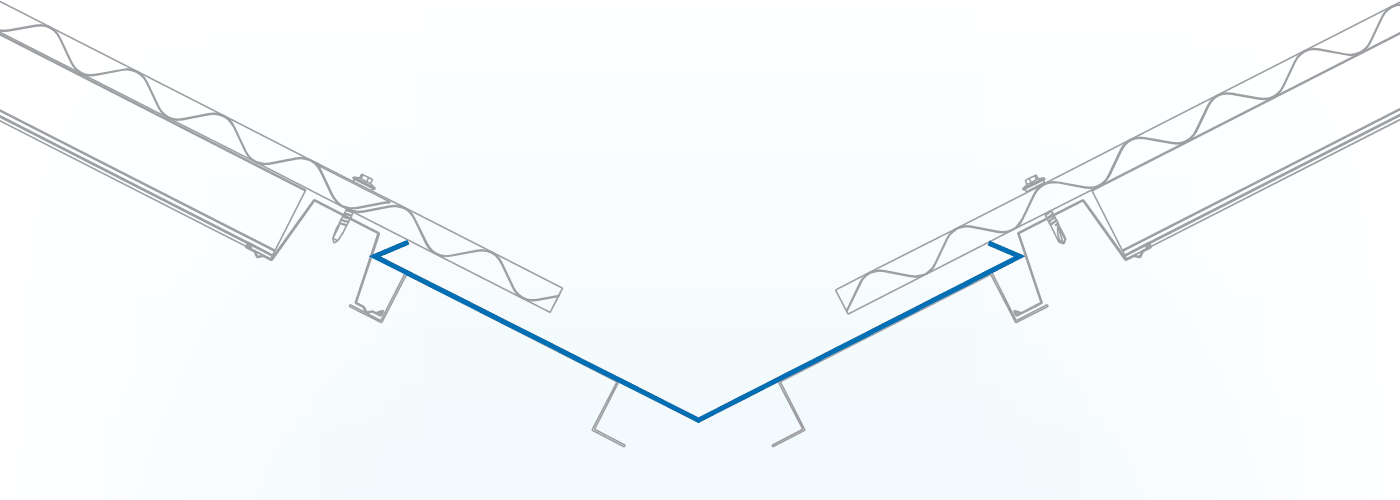

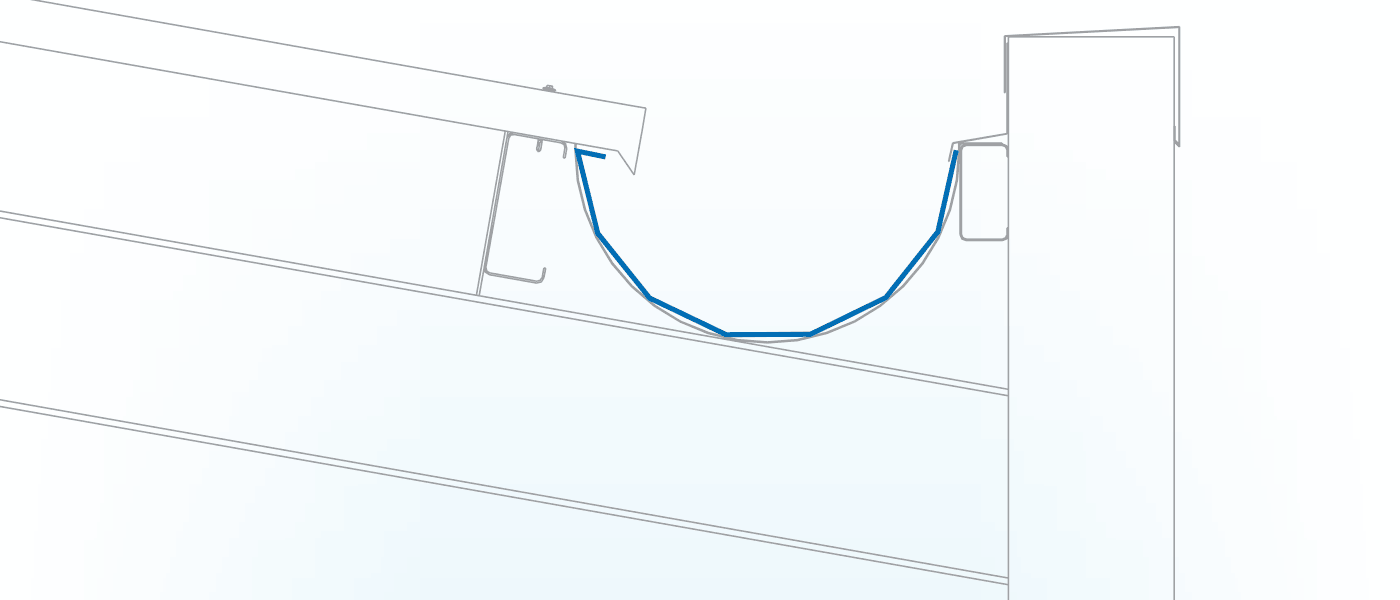

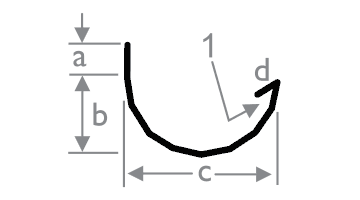

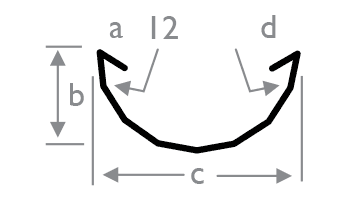

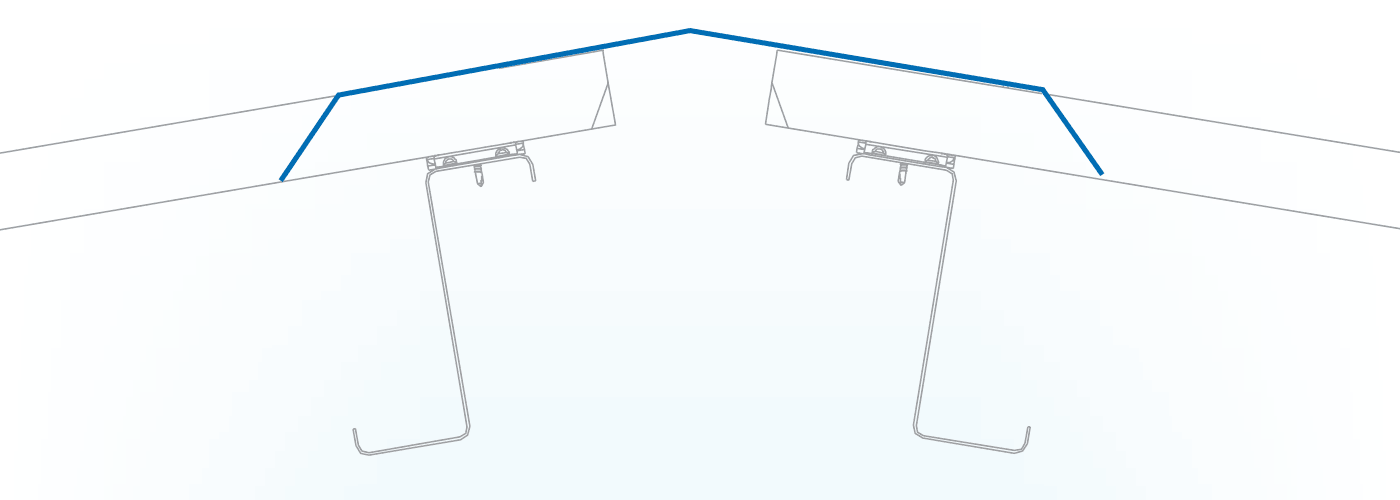

Valley Gutters

A shallow gutter formed to suit the angle between two internal slopes of a roof. Its design will usually include a return at each edge to minimise the possibility of water spillage into the roof space. Depending on the size and application additional internal stiffening ribs may be included.

22

Standard Valley

23

Valley With Upstands

24

Valley With Squashfolds

25

Segmented Valley

26

Segmented Valley

With Upstand

18

Deep Valley

With Square Ribs

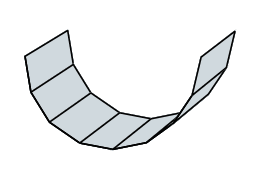

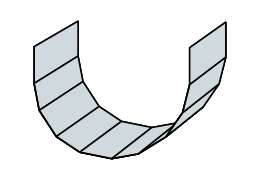

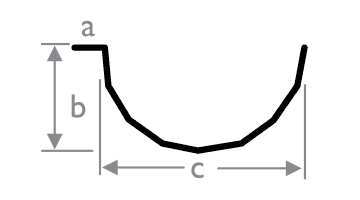

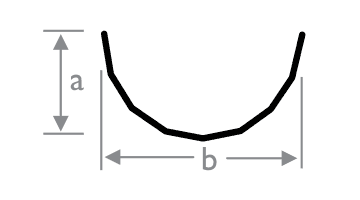

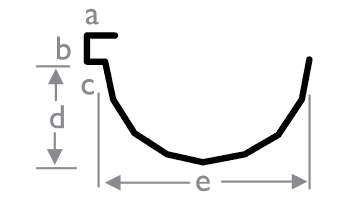

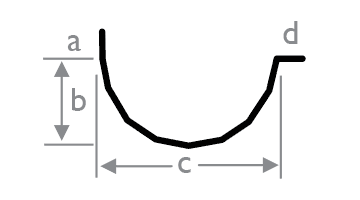

Trough Gutters

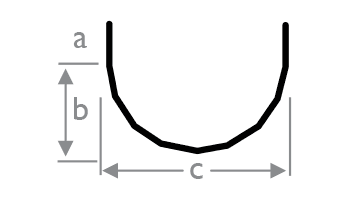

A half round segmented gutter formed into a trough. It is formed between a roof surface and a parapet wall or between two roof surfaces and is available with infold, outfold, splashback and squashfold edges. Usually supported by heavy gauge straps, trough gutters are very efficient and have better self cleaning properties than box gutters. In most cases the depth will not exceed half the width.

28

Segmented Trough

Gutter with Outfold

29

Standard Segmented

Trough Gutter

30

Segmented Trough

Gutter With Splashback

31

Part Segmented

Trough Gutter

32

Segmented Eaves Gutter

With Standard Bead

33

Segmented Trough Gutter

With Modified Bead

34

Segmented Trough Gutter

With Modified Splashbacks

35

Segmented Trough Gutter

With Standard Splashbacks

36

Segmented Trough Gutter

With Outfold & Raised Side

37

Segmented Trough Gutter

With Double Outfolds

38

Segmented Trough Gutter

With Raised Sides

39

Segmented

Quad Gutter

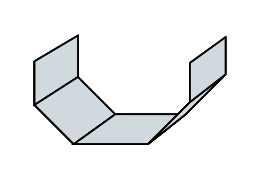

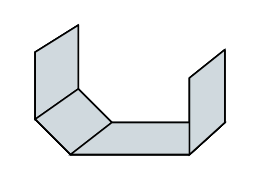

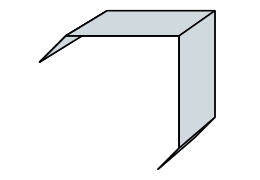

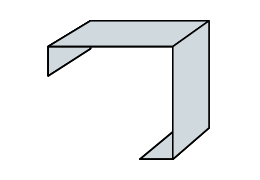

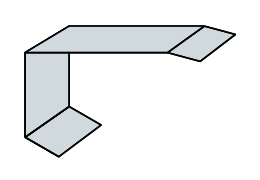

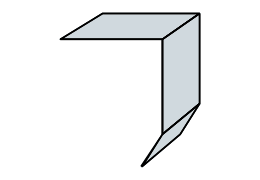

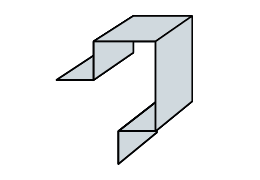

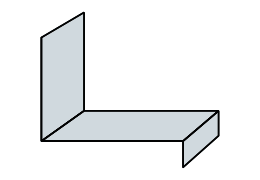

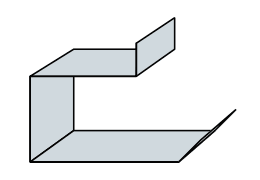

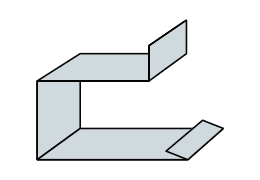

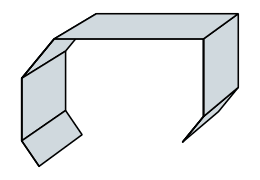

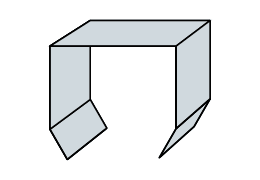

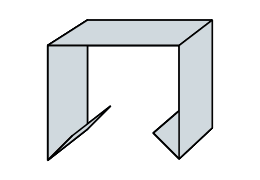

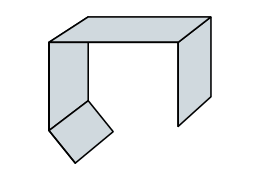

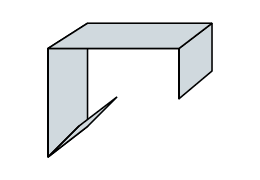

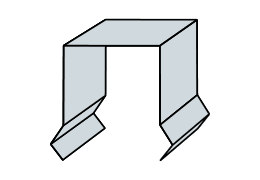

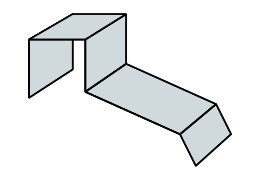

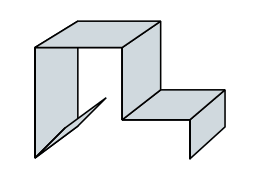

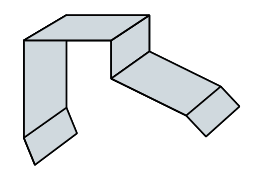

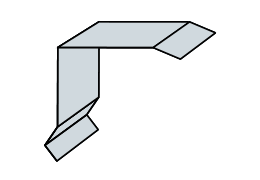

Corner Flashings

A folded piece of steel used for waterproofing wall sheeting where two walls meet to form an external corner. Where used with steel sheet walling it should lap at least one rib and a recommended two ribs for maximum water proofing.

40

Standard Corner Flashing

41

Square Corner Flashing

42

Offset Corner Flashing

43

Modified Corner Flashing

44

Standard Internal

Corner Flashing

45

Internal Corner With

Internal Squash Fold

46

Internal Corner With

External Squash Fold

47

Bulky Corner Flashing

48

Stepped Corner Flashing

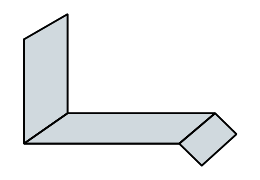

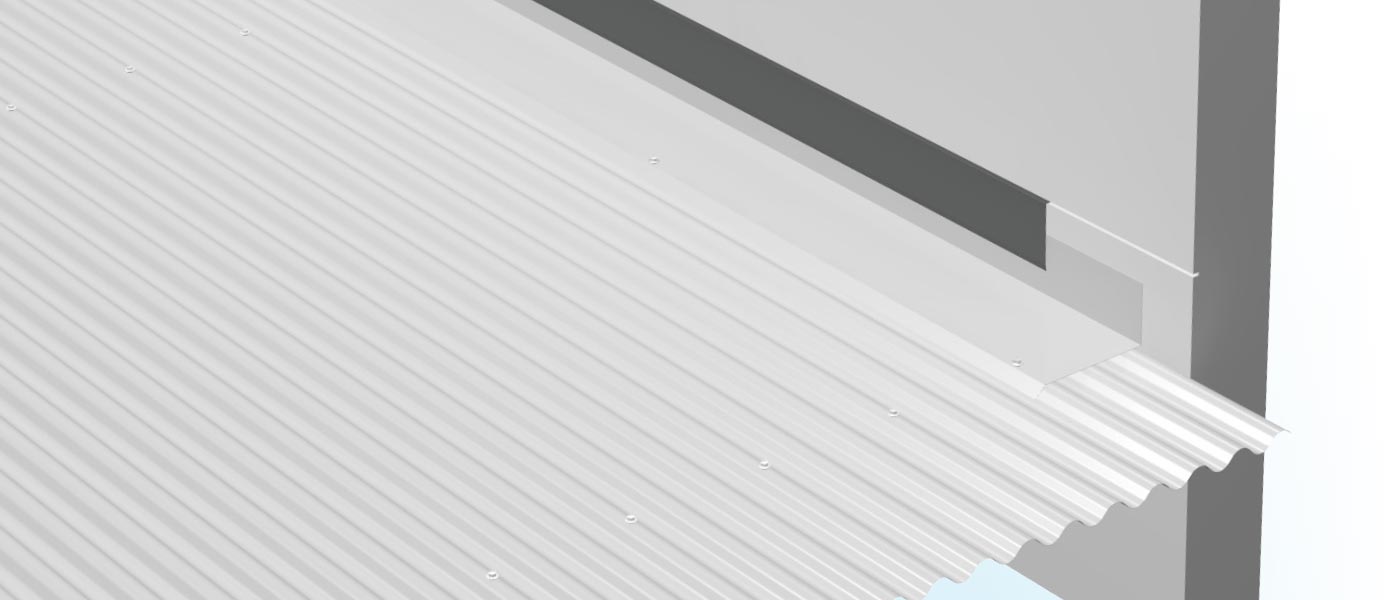

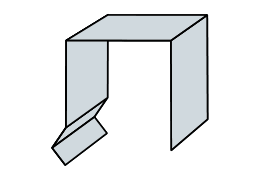

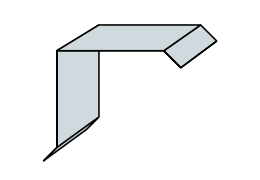

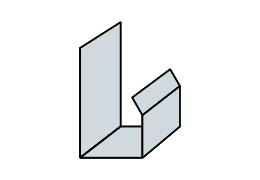

Apron Flashings

A folded piece of steel used to prevent water from penetrating the space where a vertical surface intersects a roof. Where used with steel sheet roofing it should lap at least one rib and a recommended two ribs for maximum water proofing. Wider apron flashings are advised when the base of the flashing faces into the prevailing wind.

49

Apron Flashing

50

Apron Flashing

With 90° Turndown

51

Apron Flashing With

Pole Plate And 135° Break

52

Apron Flashing With

Pole Plate And 90° Break

53

Apron Flashing With

Splayed Pole Plate

54

Side Flashing

With Pole Plate

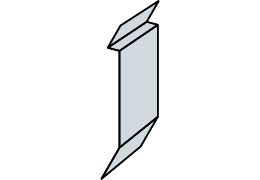

Foot Moulds

A folded piece of steel used to finish the base of a vertical surface, in such a way as to prevent water penetration. It also provides an edge to an adjoining soffit. Typical applications are in facades and to finish overhanging canopies. The flashing also prevents water contact to the ends of sheeting.

55

Standard Foot Mould

56

Foot Mould With Squashfold

57

Square Foot Mould

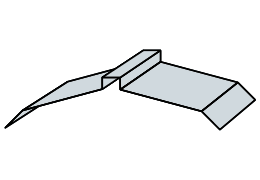

Pole Plate Flashings

A purpose made flashing used to seal the join between the end of a roof and masonry wall. A “V” groove end locates into either a preformed reglet, or a cut in the masonry wall providing a water resistant join to the roof and wall connection. When installed, pole plate flashings (often called chimney flashings) can either be stepped to conform to brick courses or left straight, for a more modern appearance.

58

Pole Plate Flashing

59

Pole Plate Flashing

With 90° Break

60

Pole Plate Flashing

With 135° Break

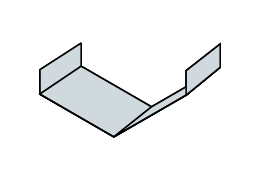

Sill Flashings

A steel sheet used to cap building framework and external brickwork at the base of a window or door frame. It also prevents water from pooling in these areas.

61

Sloping Sill Flashing

62

Square Sill Flashing

63

Square Sill Flashing

With Return

64

Z Flashing With Offset

65

Plain Sill Flashing

66

Sill Flashing

With Drip Edge

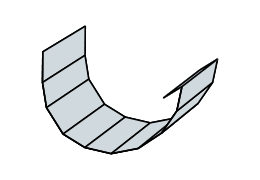

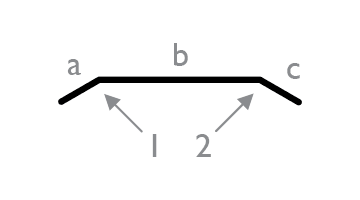

Ridge Flashings

A steel covering over the ridge to provide a continuous cover and effective weather seal between two slopes. The size of the edge break should conform with the rib height of the steel roofing to which the ridge is attached. Good roofing practice is to notch this edge break to neatly fit around each rib of the roof sheet.

67

Cover Flashing

68

3 Break

Ridge Flashing

69

Raised Top Ridge

Chimney Flashings

A folded steel sheet commonly used to provide a weather sealed base around chimneys to prevent water penetration. It is often made as a two piece flashing to provide flexibility in installation.

70

Standard

Chimney Flashing

71

Chimney Flashing

With Splay

72

Chimney Flashing

With Outfold

73

Chimney Flashing

With Pole Plate

74

Chimney Flashing

With Box Gutter

75

Chimney Flashing

And Cap

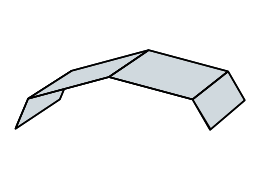

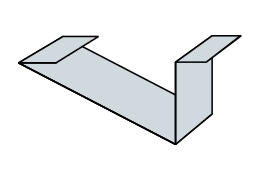

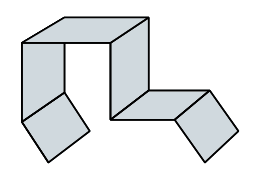

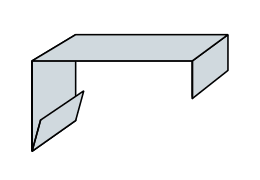

Parapet Capping

A covering used to waterproof and cap the ends of vertical sheets or masonry walls. A stiffening edge or break is often applied to the legs of the parapet cap for a more appealing appearance, and to minimise oilcanning of the steel. Ensure that these recommendations are taken into account when measuring the flashing. It is also important to ensure that water does not pool on top of the cap, to prevent water seeping into the building.

76

Standard Parapet

Capping With Chamfer

77

Standard

Parapet Capping

78

Standard Parapet Capping

With Return Hooks

79

Parapet Capping

With Fold One Side

80

Parapet Capping

With Hook One Side

81

Parapet Capping With

Hook And Overflashing

82

Parapet Cap With

´V´ Both Sides

83

Parapet Cap with

´V´ One Side

84

Combined Parapet

And Apron Flashing

85

Angled Combined Parapet

And Apron Flashing

86

Angled combined Parapet

And Apron With 90° Break

87

Combined Parapet

And Apron With break

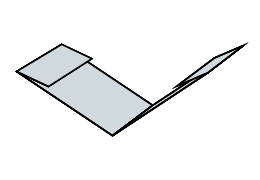

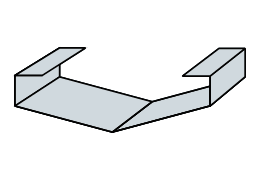

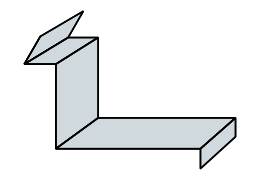

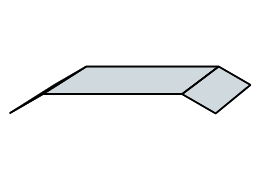

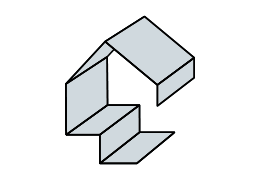

Barge Capping

A folded sheet used to waterproof the junction between a fascia or barge board and roof sheeting. The size of the edge break should conform with the rib height of the steel roofing to which the ridge is attached.

88

Standard Square

Barge Cap

89

Standard Barge

Cap With 90° Break

90

Barge With Hook

But No Break

91

Barge With Hook

92

Barge With ´V´

93

Angled Barge

With 90° Break

94

Angled Barge With

135° Break

95

Garage Barge

96

Square Top Barge

97

Square Top Barge

With 90° Break

98

Square Top Barge

With Drip Edge

99

Simple Barge

With 90° Break

Miscellaneous Flashings

100

Overcap

101

Standard Back Channel

102

Fascia Capping

Flashing Materials

Stratco flashings are available in galvanised, unpainted zinc/al, pre-painted colour steel, aluminium, stainless steel, and copper. They can be folded in a wide selection of gauges, ranging from 0.4mm to 3.0mm. The availability of gauges may vary between states.

| Material | Base Metal Thickness (mm) | |||||||

| Galvanised | 0.40* | 0.55* | 0.80* | 1.00* | 1.20* | 1.60** | 2.00† | 3.00† |

|---|---|---|---|---|---|---|---|---|

| Zinc/al | 0.40* | 0.55* | 0.80* | 1.00* | 1.20* | - | - | - |

| Colour | 0.40* | 0.55* | - | - | - | - | - | - |

| Ultra | - | 0.55* | - | - | - | - | - | - |

| Alum (Mill Finish) | - | - | - | 1.00# | 1.20 | - | - | - |

| Stainless Steel 304/2B (NT) |

0.55 | - | 0.90 | - | 1.20 | 1.60 | Not available in all states. Please check prior to ordering. |

|

| Stainless Steel 316/2B (SA) |

0.55 | 0.70* | 0.90 | - | 1.20 | 1.60 | ||

* Maximum length 8000mm, ** Maximum length 6000mm, † Maximum length 2400mm, # Maximum length 4000mm Note: Maximum coil width 1200mm.

Receiving Orders

Stratco prefer to receive orders by fax or by Stratco Direct™. Stratco will accept, but take no responsibility for orders placed by phone.

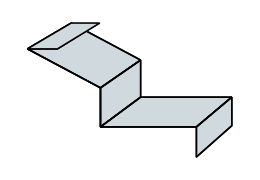

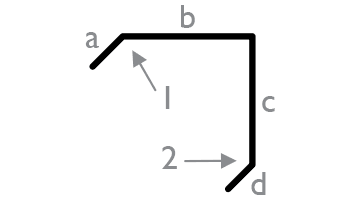

Flashing Drawings

Standard Flashings

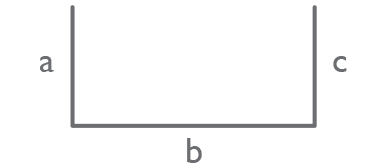

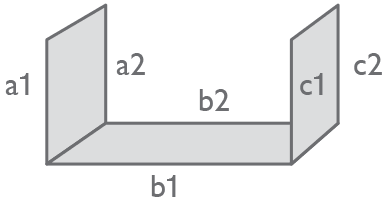

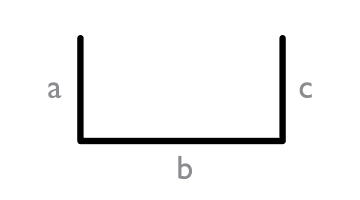

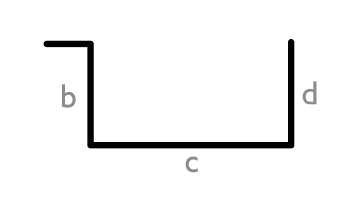

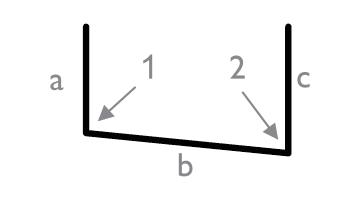

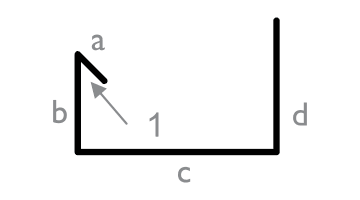

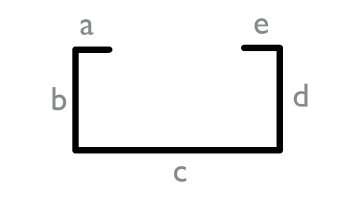

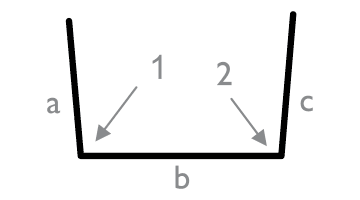

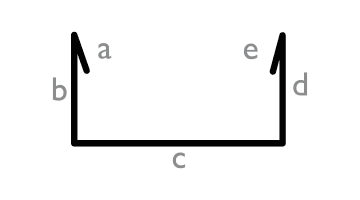

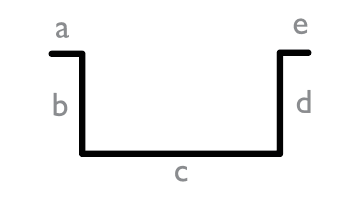

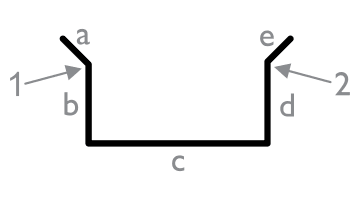

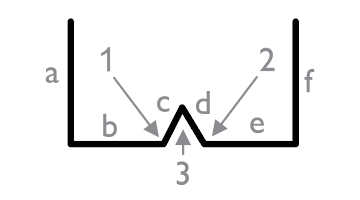

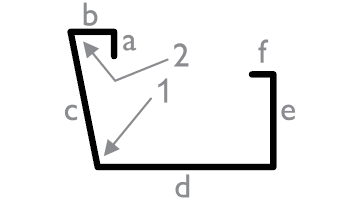

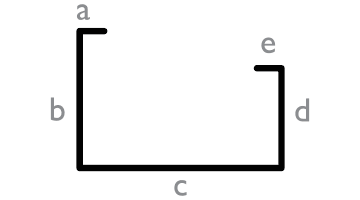

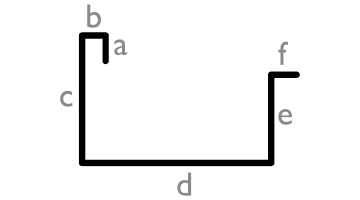

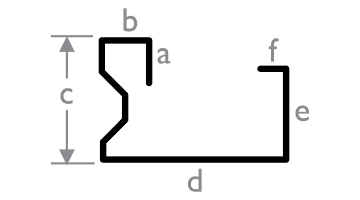

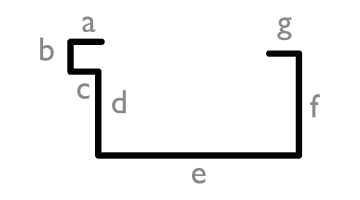

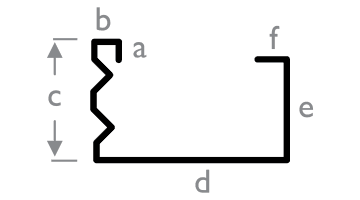

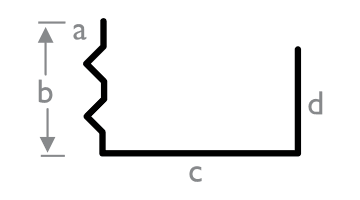

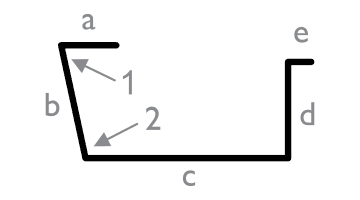

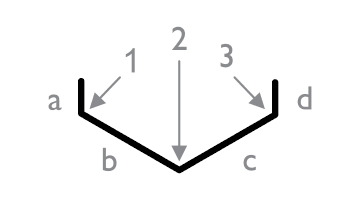

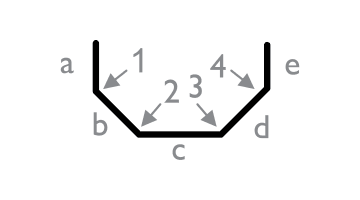

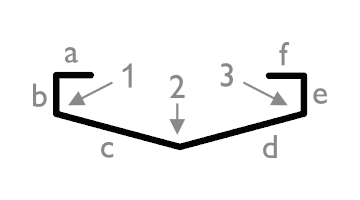

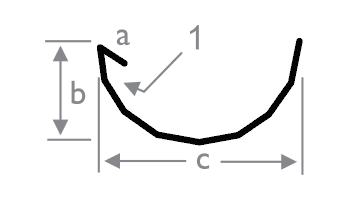

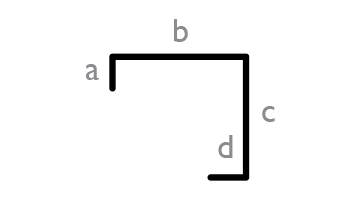

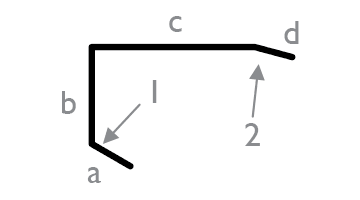

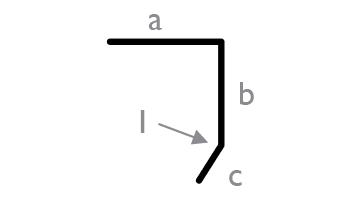

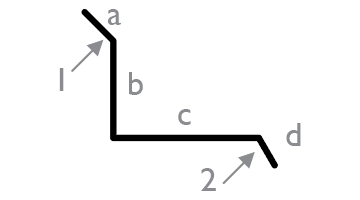

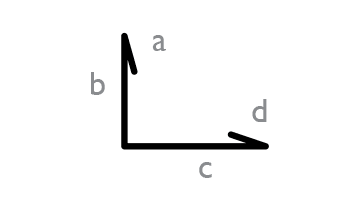

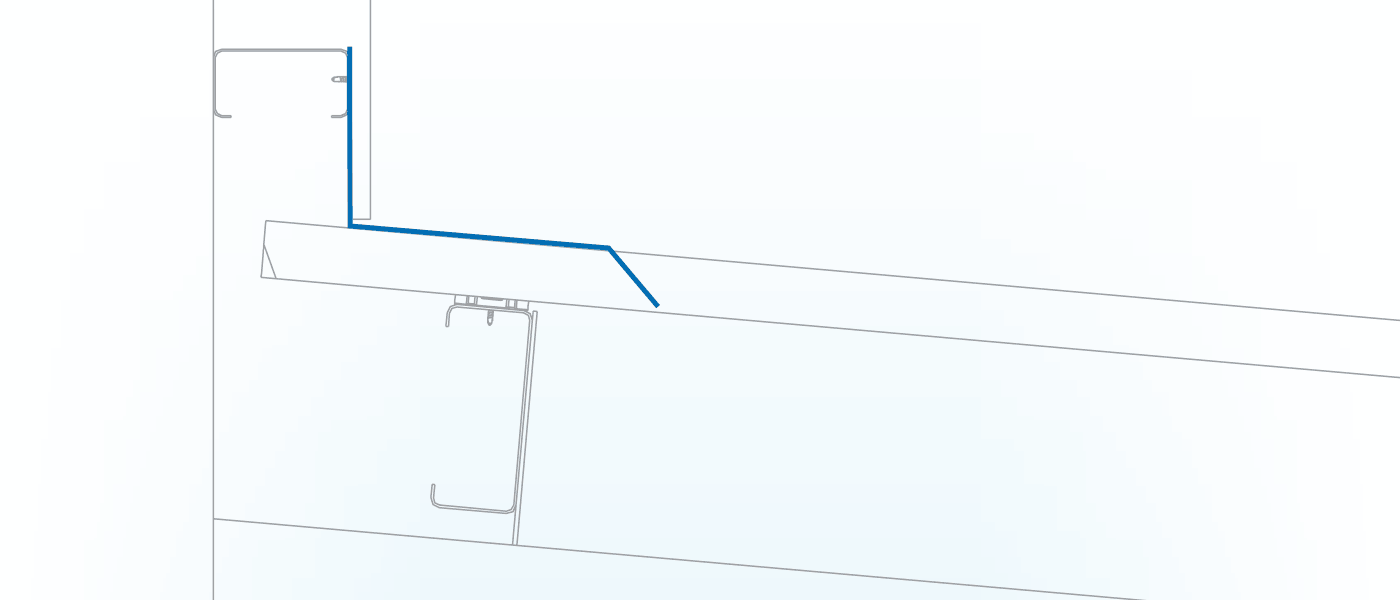

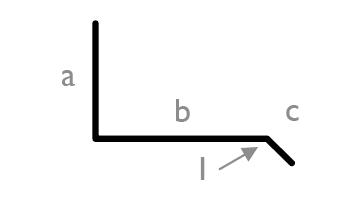

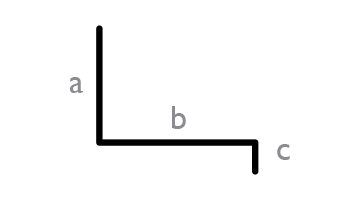

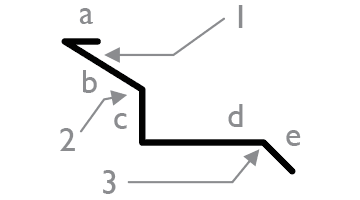

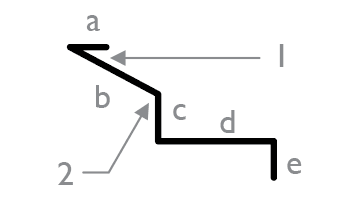

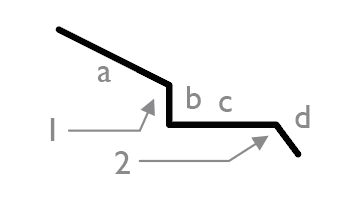

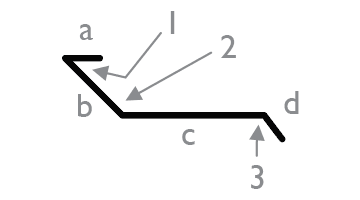

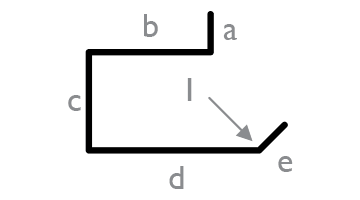

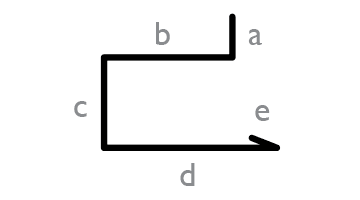

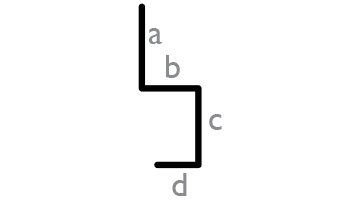

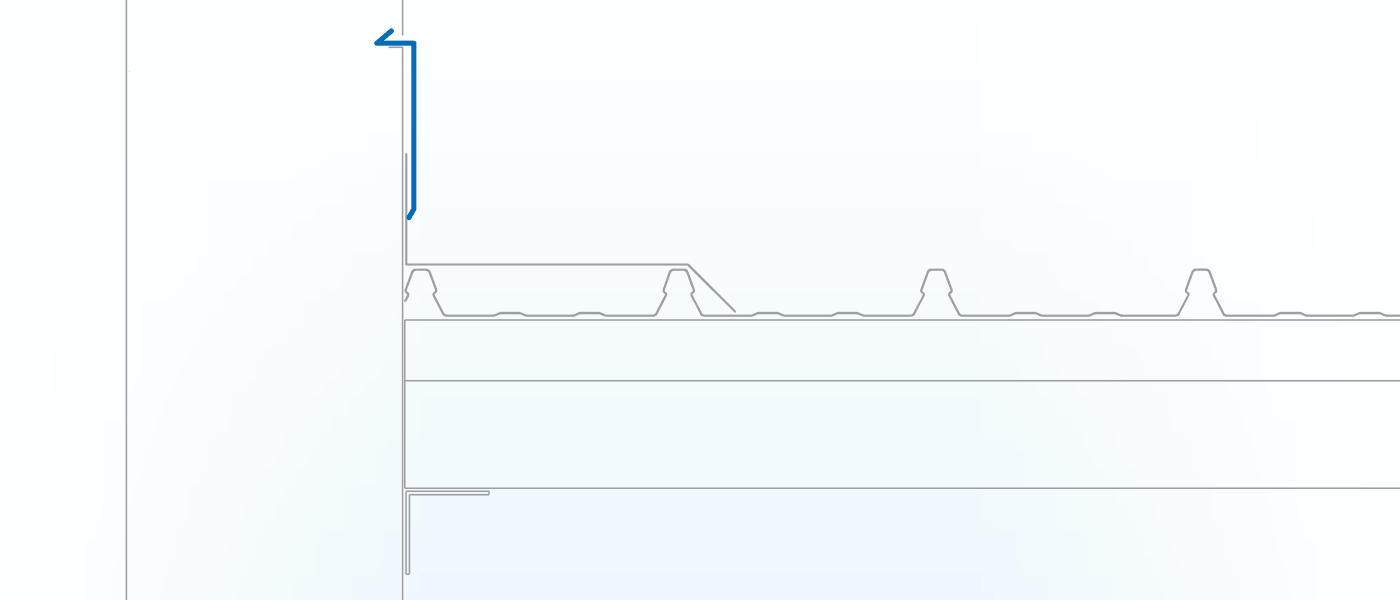

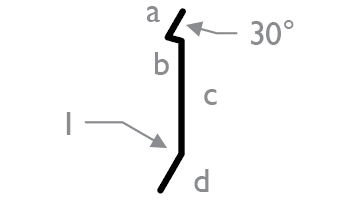

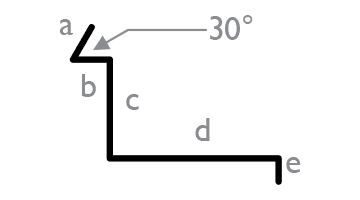

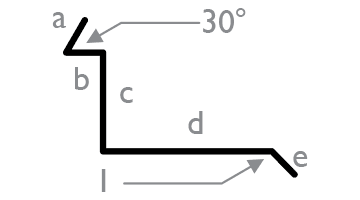

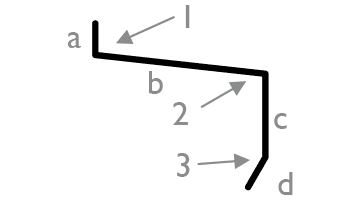

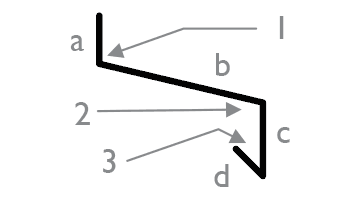

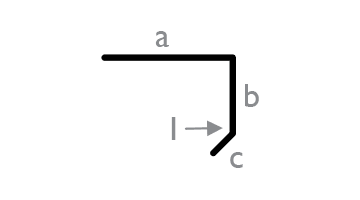

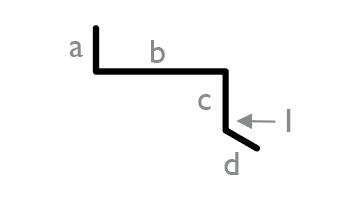

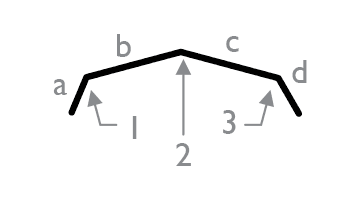

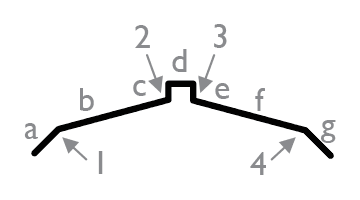

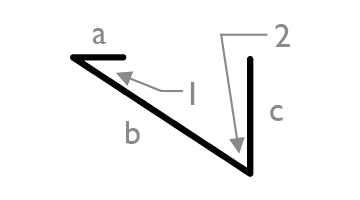

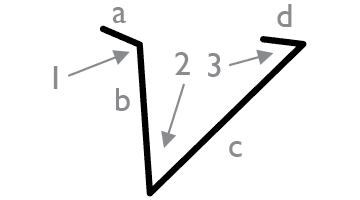

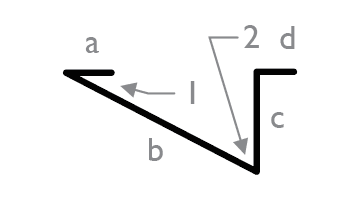

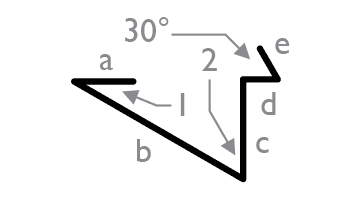

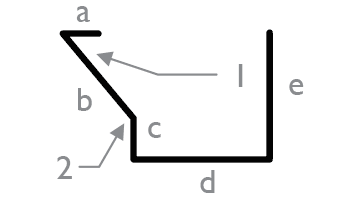

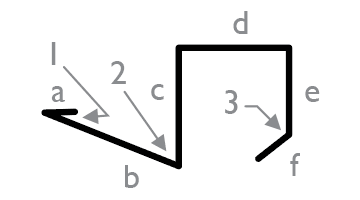

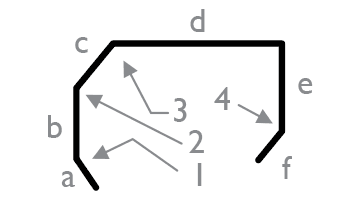

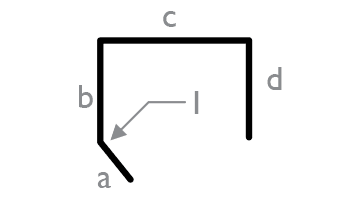

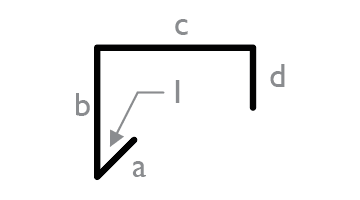

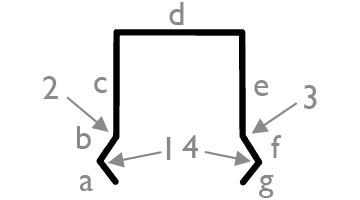

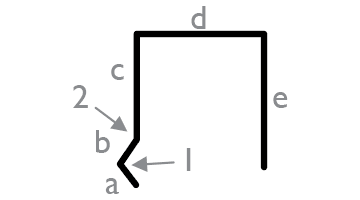

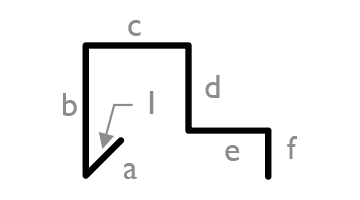

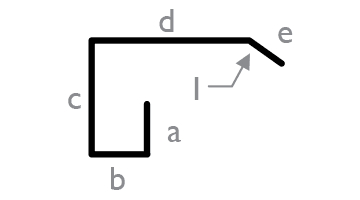

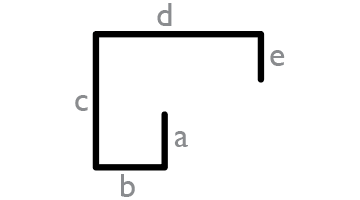

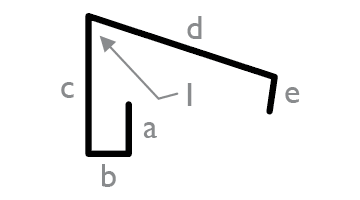

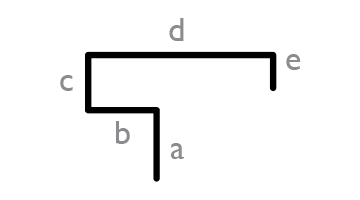

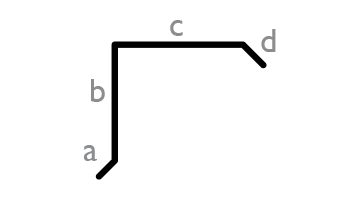

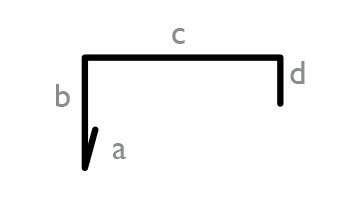

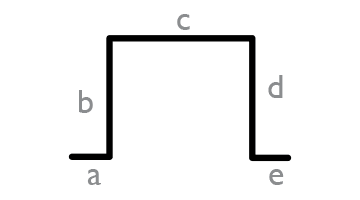

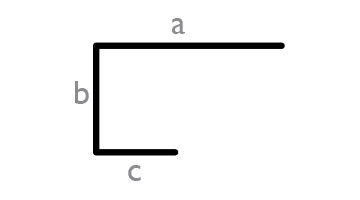

When drawing standard flashings, letters describe the dimensions of each plane on the flashing, and numbers describe the included angle. You need to advise us of all dimensions, and identify any angle that is not 90 degrees.

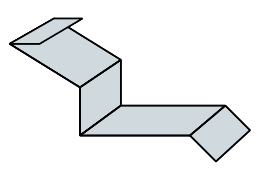

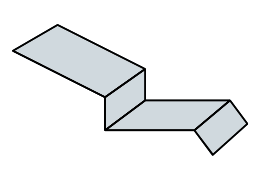

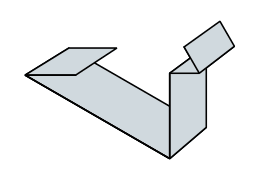

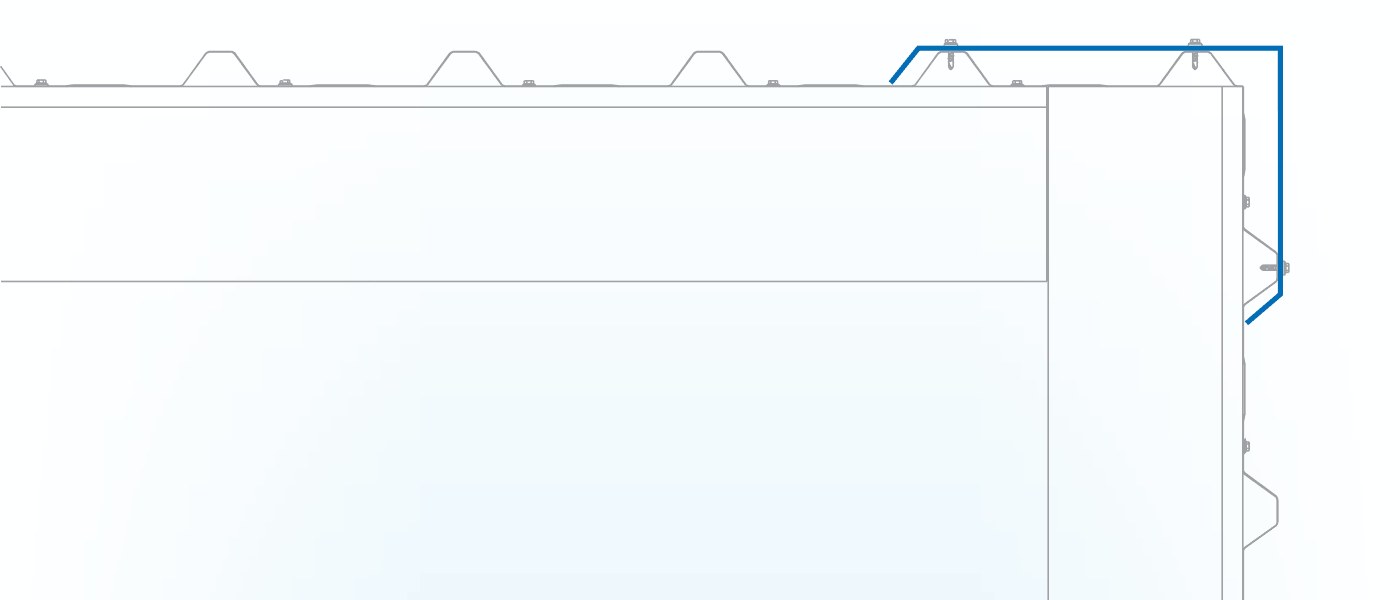

Tapered Flashings

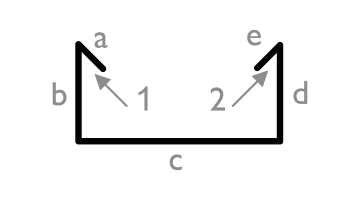

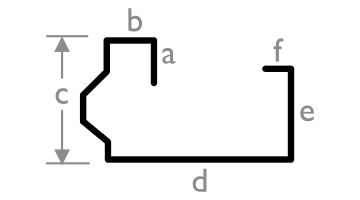

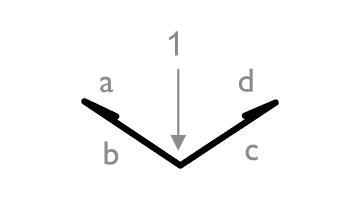

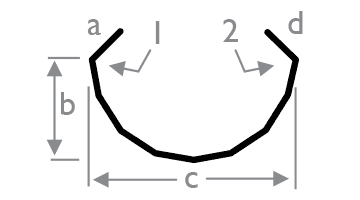

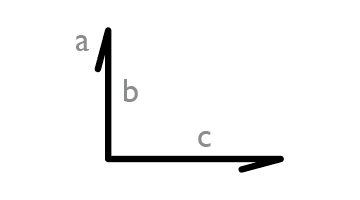

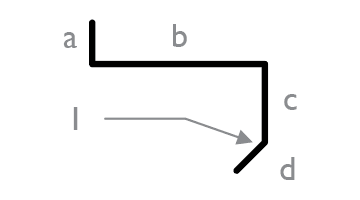

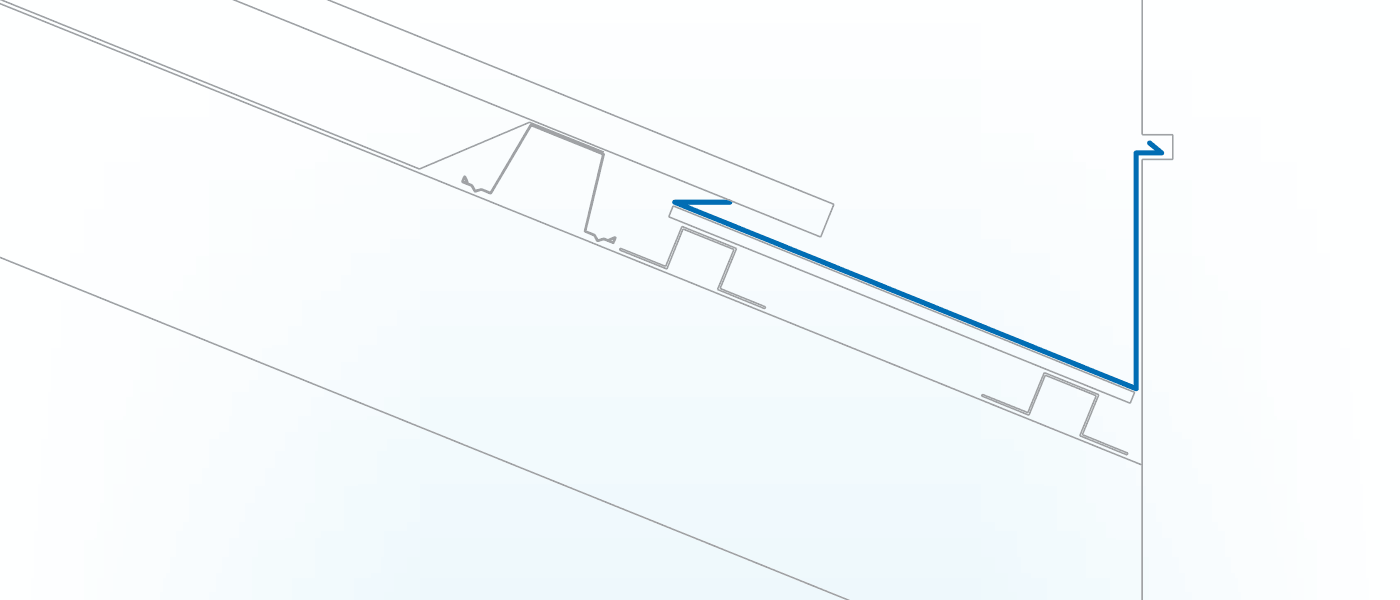

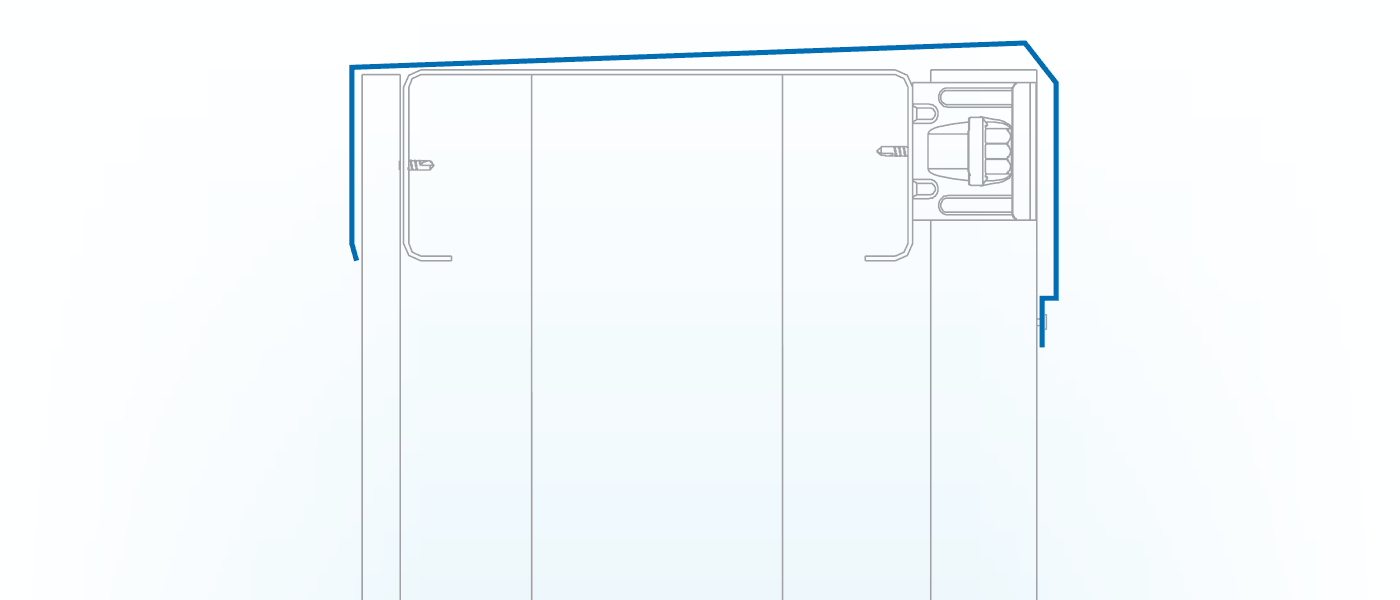

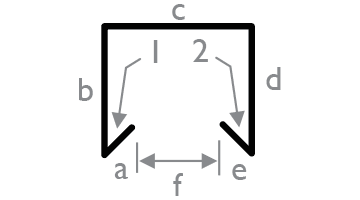

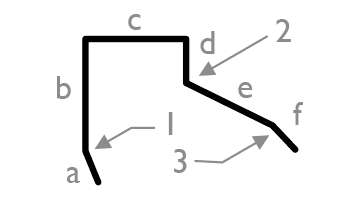

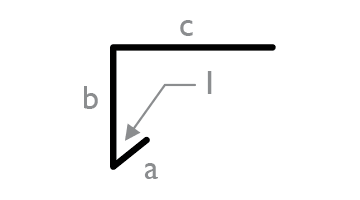

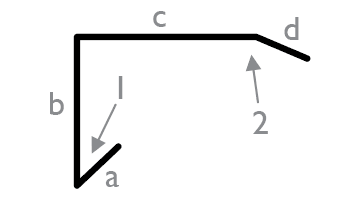

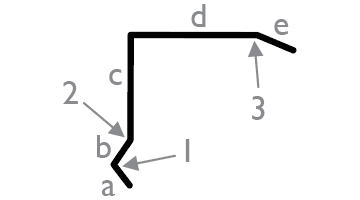

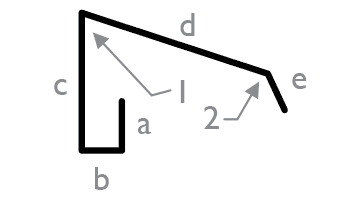

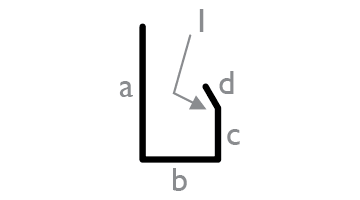

Tapered flashings use the same system as non-tapered flashings. Angles will always be constant throughout the flashing. The dimensions closest to you described as 'NEAR' (as shown in the drawing) have a '1' added to the letter representing the dimension, and the dimensions furthest away described as 'FAR' have the number '2'. Box gutter (1) would therefore be described as shown in the diagram on the right.

Order Methods

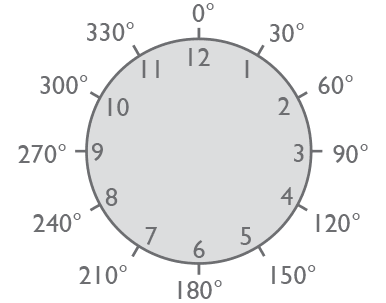

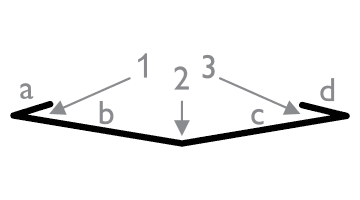

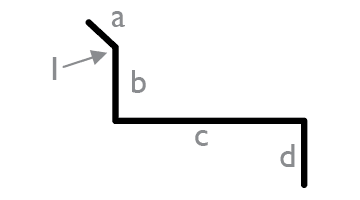

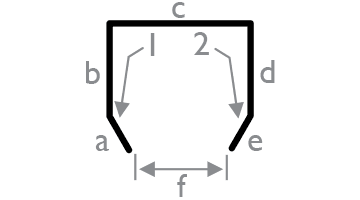

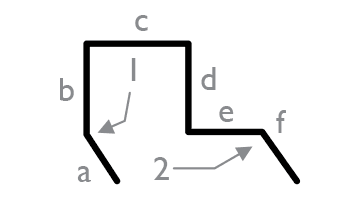

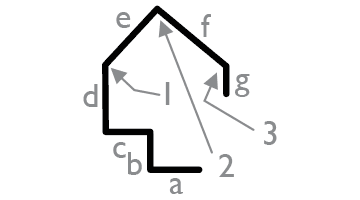

Clock Method For Placing Orders By Phone

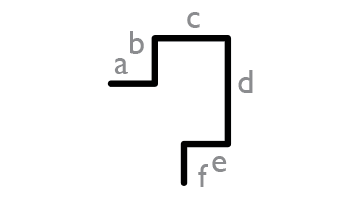

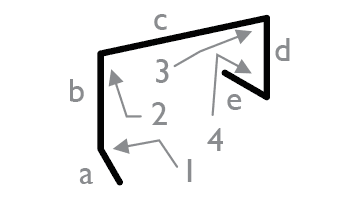

Commence at the centre of the clock. Draw a straight line from the centre to the number on the clock (1-12) at the required angle, representing the first line of your flashing drawing. Where the pen stops becomes the centre of the clock for the next line. Complete the flashing using this method. For tapered flashings quote nearest edges first. Repeat for the back (use the same letters) unless otherwise indicated.

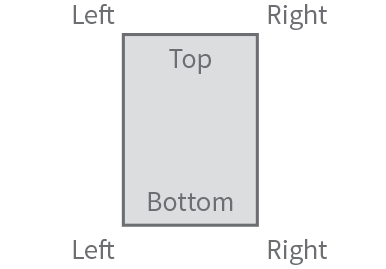

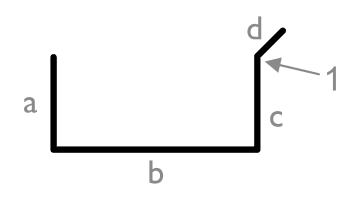

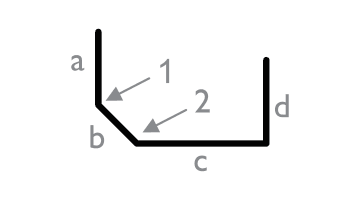

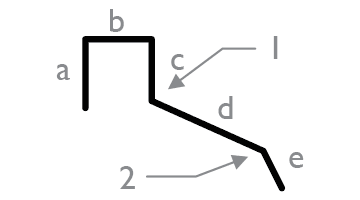

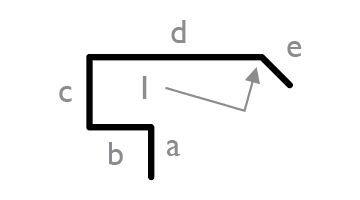

Page Drawing Method

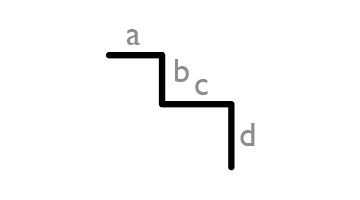

Begin drawing the flashing at the centre of the page. Describe the direction of the line as you draw it. Advise if the line moves vertically up or down the page, horizontally left or right, or to which page corner. Advise the length of the line. Do this for every line in the flashing. Advise of any included angles.

Flashing Profiles

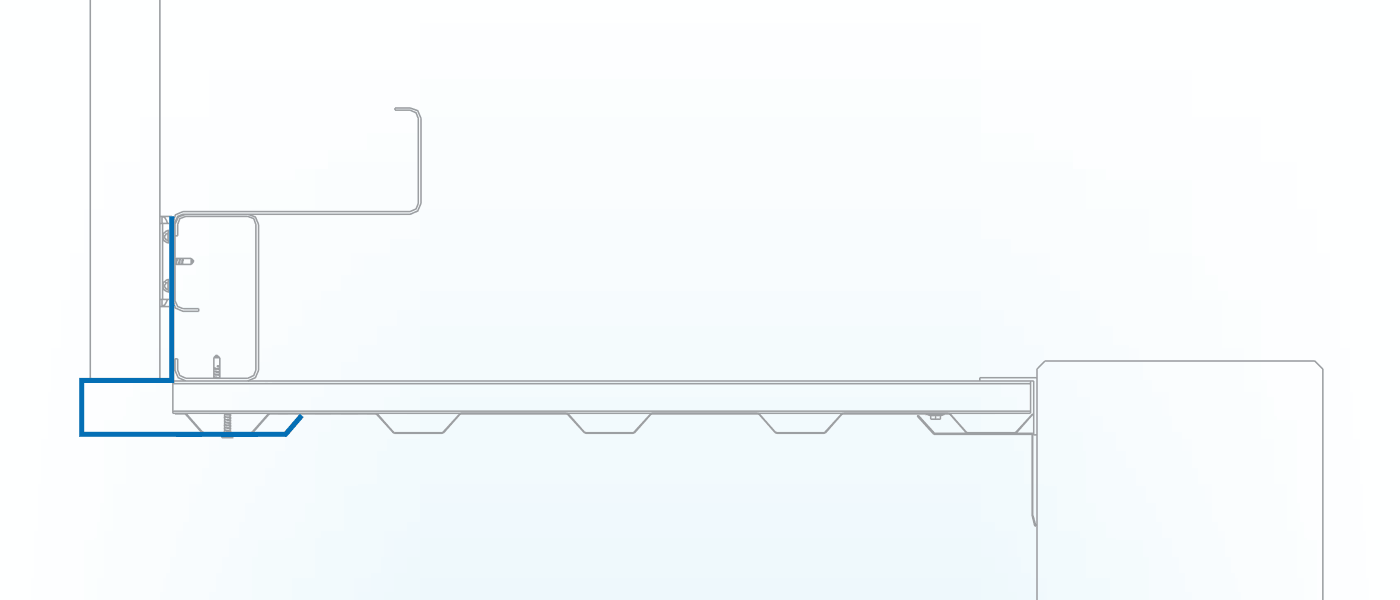

Box Gutters

A square or rectangular gutter that is used within the boundaries of the roof. It may be formed between a roof surface and a parapet wall or between two roof surfaces. Available with infold, outfold, splashback and squashfold edges. This gutter is usually supported on a box gutter board to improve strength and stiffness and to minimise damage caused by roof traffic.

1

Standard Box Gutter

2

Box Gutter

With Single Outfold

3

Angled Box Gutter

4

Box Gutter

With Double Splashbacks

5

Box Gutter

With Single Splashback

6

Box Gutter

With Double Infolds

7

Box Gutter

With Double Splay

8

Box Gutter

With Squashfolds

9

Box Gutter

With Double Outfolds

10

Box Gutter

With Double Upturns

11

Box Gutter

With Single Upturns

12

Box Gutter

With 'V' Stiffening Rib

Industrial Eave Gutters

A purpose made external gutter which is located at the edge of an industrial roof. It is usually supported by heavy gauge brackets that have been designed specifically to suit the industrial eaves gutter shape. When made in larger sizes special attention should be given to minimising oil canning of flat surfaces by adding extra ribs to the design.

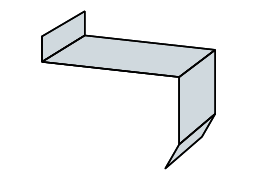

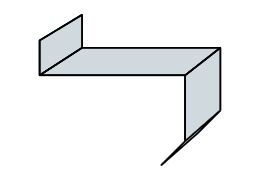

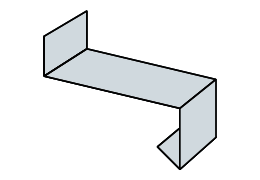

13

Industrial Eaves Gutter

With Return

14

Basic Industrial

Eaves Gutter

15

Industrial Eaves

With Outfold

16

Industrial Eaves

With Stiffening Rib

17

Industrial Eaves Gutter

With Bead

18

Fancy Industrial Eaves

Gutter With Bead

19

Two Rib Industrial

Eaves Gutter

20

Industrial Eaves Gutter

With Splay And Outfold

21

Industrial Eaves Gutter

With Protruding Rib

Valley Gutters

A shallow gutter formed to suit the angle between two internal slopes of a roof. Its design will usually include a return at each edge to minimise the possibility of water spillage into the roof space. Depending on the size and application additional internal stiffening ribs may be included.

22

Standard Valley

23

Valley With Upstands

24

Valley With Squashfolds

25

Segmented Valley

26

Segmented Valley

With Upstand

18

Deep Valley

With Square Ribs

Trough Gutters

A half round segmented gutter formed into a trough. It is formed between a roof surface and a parapet wall or between two roof surfaces and is available with infold, outfold, splashback and squashfold edges. Usually supported by heavy gauge straps, trough gutters are very efficient and have better self cleaning properties than box gutters. In most cases the depth will not exceed half the width.

28

Segmented Trough

Gutter with Outfold

29

Standard Segmented

Trough Gutter

30

Segmented Trough

Gutter With Splashback

31

Part Segmented

Trough Gutter

32

Segmented Eaves Gutter

With Standard Bead

33

Segmented Trough Gutter

With Modified Bead

34

Segmented Trough Gutter

With Modified Splashbacks

35

Segmented Trough Gutter

With Standard Splashbacks

36

Segmented Trough Gutter

With Outfold & Raised Side

37

Segmented Trough Gutter

With Double Outfolds

38

Segmented Trough Gutter

With Raised Sides

39

Segmented

Quad Gutter

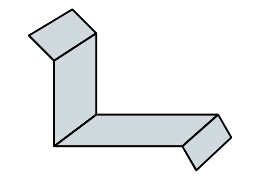

Corner Flashings

A folded piece of steel used for waterproofing wall sheeting where two walls meet to form an external corner. When used with steel sheet walling it should lap at least one rib and a recommended two ribs to ensure maximum water proofing.

40

Standard Corner Flashing

41

Square Corner Flashing

42

Offset Corner Flashing

43

Modified Corner Flashing

44

Standard Internal

Corner Flashing

45

Internal Corner With

Internal Squash Fold

46

Internal Corner With

External Squash Fold

47

Bulky Corner Flashing

48

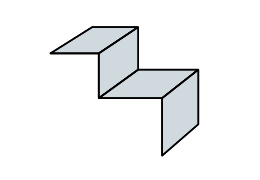

Stepped Corner Flashing

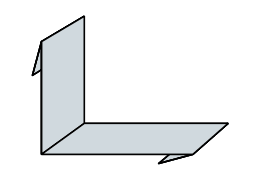

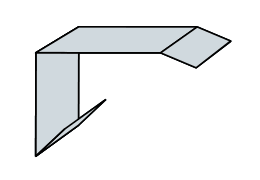

Apron Flashings

A folded piece of steel used to prevent water from penetrating the space where a vertical surface intersects a roof. Where used with steel sheet roofing it should lap at least one rib and a recommended two ribs for maximum water proofing. Wider apron flashings are advised when the base of the flashing faces into the prevailing wind.

49

Apron Flashing

50

Apron Flashing

With 90° Turndown

51

Apron Flashing With

Pole Plate And 135° Break

52

Apron Flashing With

Pole Plate And 90° Break

53

Apron Flashing With

Splayed Pole Plate

54

Side Flashing

With Pole Plate

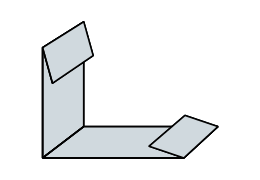

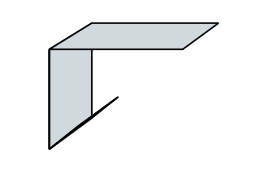

Foot Moulds

A folded piece of steel used to finish the base of a vertical surface, in such a way as to prevent water penetration. It also provides an edge to an adjoining soffit. Typical applications are in facades and to finish overhanging canopies. The flashing also prevents water contact to the ends of sheeting.

55

Standard Foot Mould

56

Foot Mould With Squashfold

57

Square Foot Mould

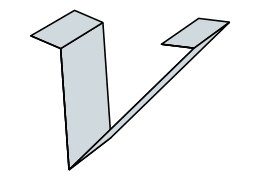

Pole Plate Flashings

A purpose made flashing used to seal the join between the end of a roof and masonry wall. A “V” groove end locates into either a preformed reglet, or a cut in the masonry wall providing a water resistant join to the roof and wall connection. When installed, pole plate flashings (often called chimney flashings) can either be stepped to conform to brick courses or left straight, for a more modern appearance.

58

Pole Plate Flashing

59

Pole Plate Flashing

With 90° Break

60

Pole Plate Flashing

With 135° Break

Sill Flashings

A steel sheet used to cap building framework and external brickwork at the base of a window or door frame. It also prevents water from pooling in these areas.

61

Sloping Sill Flashing

62

Square Sill Flashing

63

Square Sill Flashing

With Return

64

Z Flashing With Offset

65

Plain Sill Flashing

66

Sill Flashing

With Drip Edge

Ridge Flashings

A steel covering over the ridge to provide a continuous cover and effective weather seal between two slopes. The size of the edge break should conform with the rib height of the steel roofing to which the ridge is attached. Good roofing practice is to notch this edge break to neatly fit around each rib of the roof sheet.

67

Cover Flashing

68

3 Break

Ridge Flashing

69

Raised Top Ridge

Chimney Flashings

A folded steel sheet commonly used to provide a weather sealed base around chimneys to prevent water penetration. It is often made as a two piece flashing to provide flexibility in installation.

70

Standard

Chimney Flashing

71

Chimney Flashing

With Splay

72

Chimney Flashing

With Outfold

73

Chimney Flashing

With Pole Plate

74

Chimney Flashing

With Box Gutter

75

Chimney Flashing

And Cap

Parapet Capping

A covering used to waterproof and cap the ends of vertical sheets or masonry walls. A stiffening edge or break is often applied to the legs of the parapet cap for a more appealing appearance, and to minimise oilcanning of the steel. Ensure that these recommendations are taken into account when measuring the flashing. It is also important to ensure that water does not pool on top of the cap, to prevent water seeping into the building.

76

Standard Parapet

Capping With Chamfer

77

Standard

Parapet Capping

78

Standard Parapet Capping

With Return Hooks

79

Parapet Capping

With Fold One Side

80

Parapet Capping

With Hook One Side

81

Parapet Capping With

Hook And Overflashing

82

Parapet Cap With

´V´ Both Sides

83

Parapet Cap with

´V´ One Side

84

Combined Parapet

And Apron Flashing

85

Angled Combined Parapet

And Apron Flashing

86

Angled combined Parapet

And Apron With 90° Break

87

Combined Parapet

And Apron With break

Barge Capping

A folded sheet used to waterproof the junction between a fascia or barge board and roof sheeting. The size of the edge break should conform with the rib height of the steel roofing to which the ridge is attached.

88

Standard Square

Barge Cap

89

Standard Barge

Cap With 90° Break

90

Barge With Hook

But No Break

91

Barge With Hook

92

Barge With ´V´

93

Angled Barge

With 90° Break

94

Angled Barge With

135° Break

95

Garage Barge

96

Square Top Barge

97

Square Top Barge

With 90° Break

98

Square Top Barge

With Drip Edge

99

Simple Barge

With 90° Break

Miscellaneous Flashings

100

Overcap

101

Standard Back Channel

102

Fascia Capping