- Contact Us

-

Your location

Pialba QLD 4655

Your nearest store is

Hervey Bay

-

Products

Our products

Click Mania SalePatio & Outdoor Living See all

Louvre Lighting Outdoor BlindsOutdoor KitchensAll Patio & Outdoor LivingGarages, Sheds & Shed Storage See all

Cyclonic Sheds Flat Roof Sheds & Garages Gable Roof Sheds & GaragesIndustrial & Rural ShedsUmbra Awning Sheds All Garages, Sheds & Shed StorageFencing, Gates & Screening See all

All Fencing, Gates & ScreeningGift CardsMining Outdoor KitchensLawn & Garden See all

All Lawn & GardenSale Clearance All Products - Specials

- Stores

-

About

Stratco is one of the largest producers and marketers of quality building and home improvement products in Australia with a network of stores throughout the country.

- Trade

- Specifiers

- Home

- Roofing & Wall Cladding

- Colorbond® Roof & Wall Sheets

- Smoothdek 316 .40mm BMT Double Sided Colour Bark

Smoothdek 316 Patio Roofing

StratcoSKU: SMD31640DHGBABA

About this product

Strong Smoothdek verandah and patio roofing forms a smooth underside when installed. It is economical and the 50mm high self-locking ribs allow for a quick installation.For trade and project quantity discounts:

Image gallery

Form and Function

Smooth, clean and stylish verandah and patio roofing.

With a serene profile containing inherent strength, the Smoothdek 316 is ideal as a roofing material for residential patios and verandahs. The generously wide pan provides a subtle aesthetic while the 50mm rib height delivers an impressive water carrying capacity. The comfortable coverage and self locking ribs provide a rapid installation process, ensuring the Smoothdek 316 is an economical profile to install. A complementary Rooflite is also available to maximise light transmission under your roof.

Due to being made from high tensile steel, Smoothdek 316 has the ability to resist damage caused by hard impacts, making it ideal for domestic use. The strength of the profile means it works well with a low roof pitch and can cover greater spans between structural supports. The rib height also minimises the risk of wind driven rain creeping between the sheets and therefore reduces any risk of roof leakage.

Available Colours

Brochures & Installation Guides

Custom Made For Your Project

Smoothdek 316 sheets longer than 1.2 metres are rolled to the specific length you require, provided satisfactory transport and handling facilities can be arranged. If lengths longer than ten metres are required, consult your nearest Stratco for advice on handling and transport.

To give your roof a professional finish, painted self-drilling screws are available. Stratco offer a complete range of flashings and accessories for use with Smoothdek 316, and can provide professional advice on specific flashings.

Maintenance Requirements

The performance of Smoothdek 316 over time depends on its correct application and maintenance. Maintenance should be performed as often as is required to remove any dirt, salt and pollutants. Where used in severely corrosive environments, cleaning should be performed more often. It is important that screws have the same life expectancy as the cladding you have specified.

Packs of Smoothdek 316 should always be kept dry and stored above ground level while on site. If the sheets have become wet, they should be separated, wiped and placed in the open to dry.

Refer to the Stratco 'Selection, Use and Maintenance' brochure, for more detailed information about the correct use and maintenance of this product.

Ordering Smoothdek 316

Sheets are available to your required length, allowing you to minimise waste, and enhance your design options. Smoothdek 316 is available in three attractive factory pre-painted colours. Subject to the delivery location, quantity and material availability, delivery is usually within 48 hours, or at an agreed time that suits your building schedule. Unless advised differently, a one tonne maximum is usually applied to larger packs. Arrangements for unloading the truck are the responsibility of the customer, and should be arranged before ordering. When unloading you must ensure the load is adequately spread using spreaders and slings to prevent damage.

Design considerations

The minimum recommended roof pitch for 'flat' verandahs shall be 1° for Smoothdek 316. The maximum roof pitch for units to be considered 'flat' is 5°. Care must be taken to ensure the minimum roof pitch is maintained to avoid ponding of rainwater. The roof is designed to withstand actions incidental to maintenance; roof is not to be used for floor type activities. The designs contained within these span tables relate to wind classifications N1, N2, N3 and N4 applicable to non-cyclonic applications. Stratco does not accept liability for any loss or damage suffered as a result of any errors in the interpretation of these span tables.

| Material Specifications | ||

| Material Properties | Finish | 0.42 BMT |

|---|---|---|

| Minimum ‘AZ’ Coating Mass (g/m2) | Colour | 150 |

| Mass (kg / linear metre) | Colour | 1.57 |

| Mass (kg / square metre) | Colour | 4.98 |

| Yield (square metre / tonne) | Colour | 201 |

| Tensile Strength (MPa) | Colour | 550 |

| Width Coverage (mm) | Colour | 316 |

| Sheet Tolerances (mm) | Length & Width | ±5 ±2 |

| Minimum Roof Pitch | Colour | 1° |

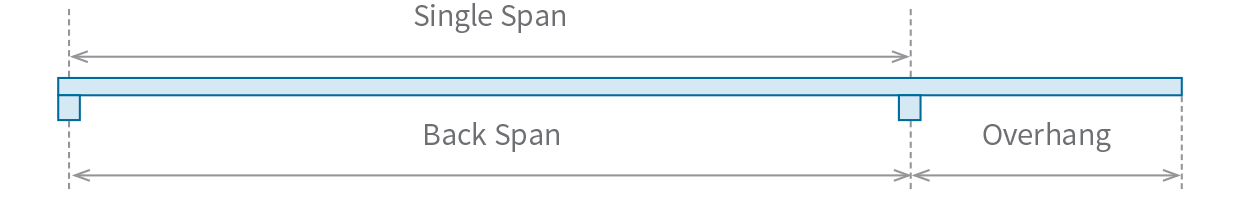

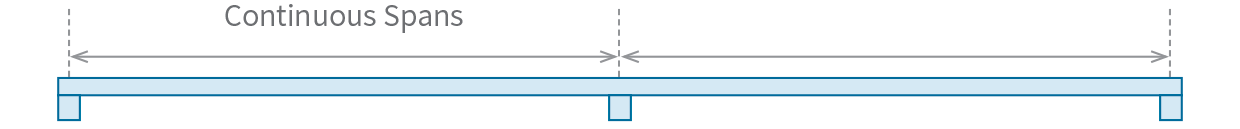

Spans

Spans for domestic patio application are suitable for 'flat' roof patios unless indicated otherwise. For a side to be considered open, walls, eaves or property boundaries shall be at least 500mm from the edge of the patio. To reduce the effect of local pressures, spans have been developed for patio units with a width not exceeding 9m.

For Smoothdek roofing in freestanding or attached gable patio application, sheet spans shall not exceed those given for one or no open sides. Alternatively, the Smoothdek 316 Wind Capacities table may be used in accordance with relevant Australian Standards to determine allowable spans for any patio application.

Spans shown for freestanding units and units with three sides open are suitable for patios considered 'empty under'. For units in which goods or materials stored under the roof are expected to block greater than 50% of any open side exposed to the wind, spans shall be taken from open two sides.

Freestanding units have been determined using Cp,n=-0.6, units with three sides open using Cp,n=-0.7, units with two sides open using Cp,n=-1.0 and spans for units with one or no open sides have been determined using Cp,n=-1.2. For single spans a local pressure factor, Kl=1.15 for serviceability and Kl=1.5 for strength have been applied and for continuous spans a value of Kl=1.5 has been applied for both strength and serviceability, in all cases local pressure is conservatively applied over the full span.

Additional engineering advice can be obtained from Stratco if any design parameters vary from those indicated above. Wind capacities given may be used by a suitably qualified engineer to determine spanning capability in varying applications including commercial or industrial applications.

Spans - Domestic Patio Application

| Domestic Carport / Verandah Spans (mm) | |||||

| Open Sides | Span Type | Wind Classification | |||

|---|---|---|---|---|---|

| N1 | N2 | N3 | N4 | ||

| Freestanding (all sides open) |

Single | 4200 | 4200 | 3200 | 2350 |

| Continuous | 4200 | 4200 | 3500 | 2750 | |

| Three | Single | 4200 | 4200 | 2900 | 2050 |

| Continuous | 4200 | 4200 | 3250 | 2300 | |

| Two | Single | 3000 | 3000 | 2150 | - |

| Continuous | 3500 | 3400 | 2400 | - | |

| One/None or Gable Patio |

Single | 2600 | 2600 | 1800 | - |

| Continuous | 3050 | 3050 | 1900 | - | |

Maximum allowable 450mm stiffened deck overhang (stiffened with gutter attachment, angle or channel section). Reference to open sides is with respect to four sided units, for a side to be considered open, the full length of the side must be open.

Wind Capacities

| Wind Capacity (kPa) | ||||||||||||

| BMT | Span Type | Limit State | Span (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1500 | 1800 | 2100 | 2400 | 2700 | 3000 | 3300 | 3600 | 3900 | 4200 | |||

| 0.40mm | Single | Serviceability | 0.97 | 0.84 | 0.73 | 0.63 | 0.54 | 0.47 | 0.42 | 0.37 | 0.35 | 0.34 |

| Strength | 10.50 | 9.19 | 7.98 | 6.88 | 5.89 | 5.01 | 4.24 | 3.57 | 3.01 | 2.56 | ||

| Continuous | Serviceability | 1.26 | 1.14 | 1.03 | 0.93 | 0.84 | 0.75 | 0.67 | 0.60 | 0.53 | 0.47 | |

| Strength | 5.37 | 4.47 | 3.68 | 2.99 | 2.41 | 1.93 | 1.55 | 1.28 | 1.11 | 1.05 | ||

The values in all the above tables are for use with steel supports with a minimum thickness of 1.0mm BMT, G550, or timber supports with fixing details as specified in 'Fixing Recommendations'. Continuous spans represent spans which are continuous over at least three supports.

Compliance

Wind Capacity Tables are based on testing in accordance with AS1562.1-1992 and AS4040.0, 1 & 2-1992. Span tables have been developed by determining wind pressures in accordance with AS4055-2012 for domestic applications. Capacity tables are in limit state format.

Fixing Recommendations

It is recommended ends of sheeting overhanging into gutter are turned down approximately 30° and this is to be done at ground level. Roofing should have a 50mm overhang into gutters and be laid with the overlapping rib facing away from the prevailing wind.

At each supporting member, pan fix roof sheets with two fasteners per sheet and remove all swarf. Ensure an additional fastener is secured within 25mm of the underlapping rib on the end sheet. In addition, secure sheeting over any parallel beams at maximum 500mm centres.

To lap sheets, press down on the lap over a support until the sheets clip together, continue working along the length of the sheet until the full length is secured. For larger spans a timber block and rubber mallet will assist in securing the lap and temporary support to the underside of the sheeting may be required.

Wall Laying Procedure

Prevailing Wind →

← Laying Direction

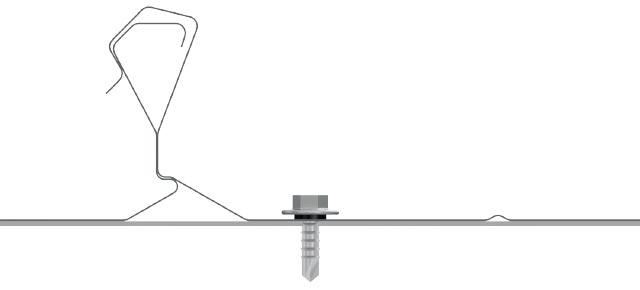

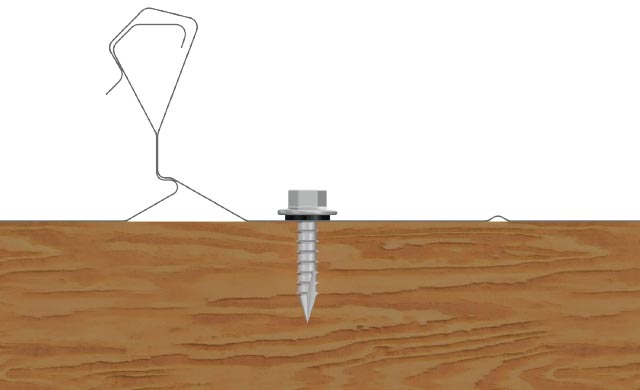

Fastener Selection

Fixing to Steel

12 x 16mm self drilling and tapping screw with neoprene washer or M6 x 25mm TS self drilling screw with seal

Fixing to Timber

12 x 25mm type 17 hex head screw with neoprene washer or M6 x 25mm TS self drilling screw with seal

Walking On Smoothdek 316

Stratco recommend foot traffic is kept to purlins for safety and to avoid damage during maintenance. Do not walk on sheet overhangs or polycarbonate Rooflite. Utilise crawl boards or ladders over roofing to avoid damage during installation and maintenance. Always ensure boards or ladders are stable and will not slide.

More Options

Tell your friends about Stratco

- Share this page

- Google Plus